An yi fim ɗin filastik da PE, PP, PVC, PS, PET, PA, da sauran resins, waɗanda ake amfani da su don marufi mai sassauƙa ko laminating layer, ana amfani da su sosai a abinci, magani, sinadarai, da sauran fannoni, waɗanda marufin abinci ya fi yawa. Daga cikinsu, fim ɗin PE shine mafi yawan amfani, mafi girman adadin fim ɗin marufi na filastik, wanda ya kai sama da kashi 40% na yawan amfani da fim ɗin marufi na filastik.

A lokacin shirya fina-finan filastik, don inganta aikin sarrafa su da tsawon lokacin sabis ɗin su, yawanci yana da mahimmanci a ƙara sinadaran zamiya. Masu zamiya na iya rage yawan gogayya na saman fina-finan filastik da kuma inganta santsi na saman su, ta haka ne za su inganta aikin sarrafa su da kuma tsawaita tsawon lokacin hidimar su.

A halin yanzu, sinadaran zamiya sun haɗa da amide, silicone mai yawan polymer, polysiloxane mai yawan copolymer, da sauransu. Nau'ikan sinadaran zamiya na fim daban-daban suna da halaye daban-daban da fa'idodi da rashin amfani, wannan yana gabatar da wasu sinadarai na zamiya na yau da kullun da kuma yadda ake zaɓar ƙarin sinadaran zamiya don fim ɗin filastik:

Magungunan slip agents na amide (gami da oleic acid amides, erucic acid amides, da sauransu):

Babban aikin da ƙarin sinadarin amide ke yi wajen samar da fim ɗin polyolefin shine samar da sifofin zamiya. Bayan sinadarin amide ya bar mold ɗin, sinadarin zamiya nan take zai yi ƙaura zuwa saman fim ɗin polymer, kuma da zarar ya isa saman, sinadarin zamiya zai samar da wani Layer mai shafawa, wanda ke rage yawan gogayya kuma ya cimma tasirin zamiya.

- Amfanin zamewar amide don Fim ɗin filastik:

Ana ƙara ƙaramin adadin ƙari a cikin shirya fim (0.1-0.3%), a cikin nau'in cakuda ko babban rukuni a cikin masana'antar sarrafawa don tabbatar da tasirin santsi iri ɗaya; kyakkyawan tasirin santsi, zai iya cimma ƙarancin adadin gogayya, ƙarancin adadin ƙari zai iya cika buƙatun.

- Rashin amfanin sinadarin amide don yin fim ɗin filastik:

Tasiri kan bugu:yana raguwa da sauri, wanda ke haifar da tasiri ga corona da bugawa.

Babban buƙatu don yanayin zafi na yanayi: misali, adadin da aka ƙara a lokacin rani da hunturu ya bambanta. Saboda yawan zafin jiki da ake ci gaba da samu a lokacin rani, man shafawa kamar erucic acid amide suna da sauƙin ƙaura akai-akai daga saman fim ɗin, kuma adadin da aka ƙaura zuwa saman fim ɗin za a tara shi yayin da lokaci ke tafiya, wanda ke haifar da ƙaruwar hazo na fim ɗin mai haske, wanda ke shafar kamanni da ingancin kayan marufi. Hakanan yana zubar da ruwa da mannewa a kan birgima na ƙarfe.

Wahalar ajiya:Abubuwan zamewar fim na amide suma suna iya ƙaura daga layin hatimin zafi zuwa layin corona bayan an gama lalata fim ɗin da kuma lokacin ajiya daga baya, wanda hakan ke shafar ayyukan da ke ƙasa kamar bugawa, laminating, da rufe zafi.

EFarin foda mai sauƙin narkewa:A cikin marufin abinci, yayin da sinadarin zamewa ke ƙaura zuwa saman, yana iya narkewa a cikin abincin, yana shafar ɗanɗanon kuma yana ƙara haɗarin gurɓatar abinci.

Manyan sinadarai masu ɗauke da silicone masu nauyin ƙwayoyin halitta masu yawa don Fim ɗin filastik:

Polysiloxane mai nauyin ƙwayoyin halitta mai matuƙar girma yana da saurin ƙaura zuwa saman saman, amma sarkar ƙwayoyin halitta tana da tsayi sosai don a iya fitar da ita gaba ɗaya, kuma ɓangaren da aka zubar yana samar da wani Layer mai ɗauke da silicone a saman, don haka yana cimma tasirin zamewar saman.

- Fa'idodi:

kyakkyawan juriya ga zafin jiki mai yawa, ruwan sama mai jinkirin sauka, musamman dacewa da layukan marufi na atomatik mai sauri (kamar fim ɗin sigari).

- Rashin amfani:

mai sauƙin tasiri ga bayyana gaskiya.

Duk da cewa ana amfani da waɗannan magungunan amide Slip Additives na gargajiya a cikin fim ɗin filastik, masana'antar ba ta da ƙalubale.

Saboda tsarinsa, halayensa na tsari, da kuma ƙaramin nauyin ƙwayoyin halitta, magungunan zamiya na fim ɗin Amide na gargajiya suna da saurin kamuwa da ruwan sama ko foda, wanda ke rage tasirin maganin zamiya sosai, yawan gogayya ba shi da tabbas dangane da zafin jiki, kuma ana buƙatar tsaftace sukurori lokaci-lokaci, kuma yana iya haifar da lahani ga kayan aiki da samfurin.

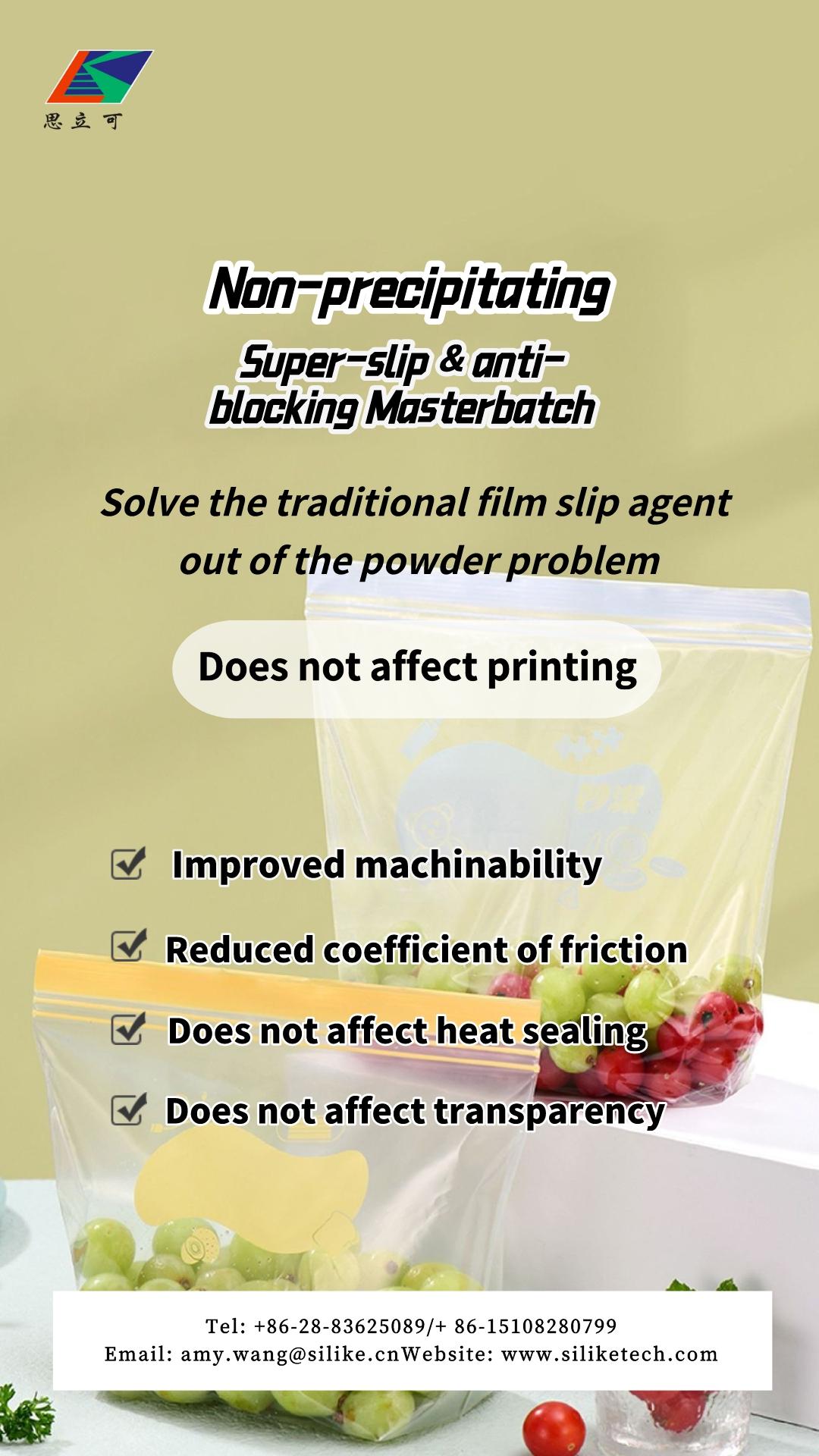

Magance Kalubalen da ke Cikin Masana'antar Fina-finan Roba:Maganin SILIKE Mai Kyau

Domin magance ƙalubale da dama tare da kayan maye na gargajiya da ake amfani da su wajen samar da fim ɗin filastik, musamman tare da kayan maye na gargajiya da aka yi da amide. Ƙungiyar bincike da ci gaba ta SILIKE ta yi nasarar magance waɗannan matsalolin tare da haɓakawani sabon abu mai ban mamaki wanda ba ya yin tsinkewa sosai kuma yana hana toshewar Masterbatch Additives- wani ɓangare naJerin SILIMER, wanda ke magance kurakuran da ke tattare da sinadarin zamiya na gargajiya, Ba ya ƙaura ta cikin layukan fim, yana tabbatar da dorewar aikin zamiya mai ɗorewa, wanda ke kawo babban ƙirƙira ga masana'antar Masana'antar Marufi Mai Sauƙi na Fim ɗin Roba. Wannan ci gaban yana ba da fa'idodi kamar ƙarancin tasiri akan bugawa, rufe zafi, watsawa, ko hazo, tare da rage CoF, kyakkyawan hana toshewa, da ingantaccen santsi na saman, yana kawar da ruwan farin foda.

Jerin SILIMER Jerin abubuwan ƙari na Masterbatch marasa ruwa mai ban sha'awa da hana toshewayana da nau'ikan aikace-aikace iri-iri kuma ana iya amfani da shi wajen samar da fina-finan BOPP/CPP/PE/TPU/EVA, da sauransu. Sun dace da yin amfani da su wajen ...

Me yasaJerin SILIMER Mara ruwa mai yawa na ƙari na Masterbatch mai zamewa da hana toshewaya fi kyau fiye da magungunan zamiya na gargajiya na amide?

Mafita Masu Ban Sha'awa Game da Fasaha ta Fim ɗin Roba

Polysiloxane mai haɗin gwiwa:SILIKE ta ƙaddamar da wani nau'in ƙari na Masterbatch wanda ba ya yin ambaliya ko kuma yana hana toshewa.- wani ɓangare naJerin SILIMER, waɗanda aka gyara su ne samfuran polysiloxane waɗanda ke ɗauke da ƙungiyoyin aiki na halitta masu aiki, ƙwayoyinsa suna ɗauke da sassan sarkar polysiloxane da dogon sarkar carbon na ƙungiyoyi masu aiki, dogon sarkar carbon na ƙungiyoyin aiki masu aiki za a iya haɗa su ta jiki ko ta sinadarai tare da resin tushe, suna iya taka rawar da za ta taka, don cimma tasirin sauƙin ƙaura ba tare da hazo ba, sassan sarkar silicone a saman, don haka suna taka rawar santsi.

Fa'idodinJerin SILIKE SILIMER Mara ruwa mai yawa, ƙari mai ban mamaki da hana toshewa.:

1. Bayanan gwaji sun nuna cewa ƙananan adadinSILIKE SILIMER 5064MB1, kumaSILIKE SILIMER 5065HBzai iya rage yawan gogayya yadda ya kamata kuma ya sami zamewa mai ɗorewa da kwanciyar hankali ba tare da la'akari da yanayi da zafin jiki ba;

2. ƘarinSILIKE SILIMER 5064MB1, kumaSILIKE SILIMER 5065HByayin shirya fina-finan filastik ba ya shafar bayyananniya na fim ɗin kuma baya shafar tsarin bugawa na gaba;

3. ƘarawaSILIKE SILIMER 5064MB1, kumaSILIKE SILIMER 5065HBa cikin ƙananan adadi yana magance matsalar cewa magungunan zamiya na amide na gargajiya suna da sauƙin narkewa ko foda, yana inganta ingancin samfurin, kuma yana adana cikakken farashi.

Kwanciyar hankali da ingantaccen aiki naJerin SILIKE SILIMER na Ƙarin Ma'aikata na Masterbatch marasa ruwa mai zurfi da hana toshewaAn yi amfani da su a fannoni da yawa, kamar samar da fim ɗin filastik, fim ɗin marufi mai haɗawa, kayan marufi na abinci, kera kayan marufi na magunguna, da sauransu. SILIKE kuma yana ba wa abokan ciniki mafita mafi aminci da aminci ga samfura. Shin kuna son maye gurbin wakilan zamiya na amide a hannunku? Shin kuna son maye gurbin wakilin zamiya na amide ɗinku don Fim ɗin filastik, ko kuna son amfani da wakilin zamiya na kare muhalli mafi aminci da inganci don Fim ɗin filastik, SILIKE yana maraba da ku don tuntuɓar mu a kowane lokaci, kuma muna fatan ƙirƙirar ƙarin damammaki tare da ku!

Lokacin Saƙo: Janairu-10-2024