A wannan zamani da ƙa'idoji da ƙa'idoji na tsaro suka fi muhimmanci, haɓaka kayan da ke tsayayya da yaɗuwar wuta ya zama muhimmin al'amari na masana'antu daban-daban. Daga cikin waɗannan sabbin abubuwa, mahaɗan masters na hana harshen wuta sun fito a matsayin mafita mai kyau don haɓaka juriyar wuta na polymers.

Fahimtar Menene Ma'adinan Bakin Wuta Mai Rage Wuta?

Haɗaɗɗun masterbatch masu hana harshen wuta sune takamaiman tsari waɗanda aka tsara don ba da kaddarorin jure wuta ga polymers. Waɗannan mahaɗan sun ƙunshi resin mai ɗaukar hoto, wanda yawanci polymer iri ɗaya ne da kayan tushe, da kuma ƙarin abubuwan hana harshen wuta. Resin mai ɗaukar hoto yana aiki azaman matsakaici don watsa sinadaran hana harshen wuta a cikin matrix na polymer.

Abubuwan da ke cikin Masarrafan Batch na Masu Rage Wuta:

1. Guduro Mai Kaya:

Resin mai ɗaukar kaya yana samar da mafi yawan masterbatch kuma ana zaɓarsa ne bisa ga dacewa da polymer ɗin tushe. Resin mai ɗaukar kaya na yau da kullun sun haɗa da polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), da sauran thermoplastics. Zaɓin resin mai ɗaukar kaya yana da mahimmanci don tabbatar da ingantaccen watsawa da dacewa da polymer ɗin da aka yi niyya.

2. Ƙarin Abubuwan da ke hana harshen wuta:

Ƙarin abubuwan da ke hana harshen wuta su ne sinadaran da ke aiki waɗanda ke hana ko jinkirta yaɗuwar harshen wuta. Ainihin, abubuwan da ke hana harshen wuta na iya zama masu amsawa ko masu ƙari. Ana iya rarraba waɗannan ƙarin zuwa rukuni daban-daban, gami da mahaɗan halogenated, mahaɗan da ke tushen phosphorus, da kuma abubuwan cika ma'adinai. Kowane rukuni yana da tsarin aikinsa na musamman wajen hana tsarin ƙonewa.

2.1 Haɗaɗɗun Halayen Halogen: Haɗaɗɗun halayen Brominated da chlorine suna fitar da halogen radicals yayin ƙonewa, wanda ke tsoma baki ga amsawar sarkar ƙonewa.

2.2 Haɗaɗɗun Phosphorus: Waɗannan haɗaɗɗun suna fitar da sinadarin phosphoric acid ko polyphosphoric acid yayin ƙonewa, suna samar da wani tsari mai kariya wanda ke danne harshen wuta.

2.3 Masu Cika Ma'adinai: Masu cike ma'adanai marasa tsari kamar aluminum hydroxide da magnesium hydroxide suna fitar da tururin ruwa idan aka fallasa su ga zafi, suna sanyaya kayan da kuma rage iskar gas mai ƙonewa.

3. Cikawa da Ƙarfafawa:

Sau da yawa ana ƙara abubuwan cikawa, kamar talc ko calcium carbonate, don inganta halayen injina na mahaɗan masterbatch. Ƙarfafawa suna ƙara tauri, ƙarfi, da kwanciyar hankali na girma, wanda ke ba da gudummawa ga aikin kayan gabaɗaya.

4. Masu daidaita abubuwa:

Ana haɗa na'urorin daidaita abubuwa don hana lalacewar matrix na polymer yayin sarrafawa da amfani. Misali, magungunan hana tsufa da na'urorin daidaita hasken UV suna taimakawa wajen kiyaye ingancin kayan idan aka fallasa su ga abubuwan da ke haifar da muhalli.

5. Launi da launuka:

Dangane da yadda ake amfani da shi, ana ƙara launuka da launuka don ba da takamaiman launuka ga mahaɗin masterbatch. Waɗannan abubuwan kuma na iya yin tasiri ga kyawawan halayen kayan.

6. Masu jituwa:

A lokuta inda na'urorin hana harshen wuta da polymer matrix ba su da jituwa sosai, ana amfani da su wajen daidaita daidaito. Waɗannan sinadarai suna haɓaka hulɗar da ke tsakanin abubuwan da ke cikin sinadaran, suna haɓaka ingantaccen watsawa da aiki gabaɗaya.

7. Magungunan rage hayaki:

Ana haɗa magungunan kashe hayaki, kamar su zinc borate ko molybdenum compounds, a wasu lokutan don rage samar da hayaki yayin ƙonewa, wani muhimmin abin la'akari a aikace-aikacen kare gobara.

8. Ƙarin Abinci don Sarrafawa:

Kayan aikin sarrafawa kamar man shafawa dawakilan watsawaSauƙaƙa tsarin kera. Waɗannan ƙarin abubuwan ƙari suna tabbatar da ingantaccen sarrafawa, hana haɗuwa, da kuma taimakawa wajen cimma wargajewar na'urorin hana harshen wuta iri ɗaya.

Abubuwan da ke sama duk sassan mahaɗan masterbatch ne na hana harshen wuta, yayin da Tabbatar da daidaiton rarraba masu hana harshen wuta a cikin matrix na polymer muhimmin bangare ne na ingancinsu. Rashin isasshen watsawa na iya haifar da rashin daidaiton kariya, lalacewar kayan aiki, da kuma raguwar amincin wuta.

Saboda haka, mahaɗan masterbatch na Flame retardant galibi suna buƙatarmasu rarrabawadon magance ƙalubalen da ke tattare da watsawa iri ɗaya na sinadaran hana harshen wuta a cikin matrix na polymer.

Musamman a fannin kimiyyar polymer mai ƙarfi, buƙatar kayan da ke hana harshen wuta mai ƙarfi tare da ingantattun halaye na aiki ya haifar da sabbin abubuwa a cikin ƙari da masu gyara. Daga cikin hanyoyin magance matsalar,masu rarraba hyperdisperssun fito a matsayin manyan 'yan wasa, suna magance ƙalubalen cimma ingantaccen watsawa a cikin tsarin hadadden Flame Retardant Masterbatch.

As masu rarraba hyperdispersmagance wannan ƙalubalen ta hanyar haɓaka rarrabawa sosai da daidaito na na'urorin hana harshen wuta a cikin babban rukunin masterbatch.

Shigar da Hyperdispersant SILIKE SILIMER 6150—wani nau'in ƙari ne da ke sake fasalin yanayin ƙwayoyin hana harshen wuta!

An ƙera SILIKE SILIMER 6150 don biyan buƙatun masana'antar polymer, kakin silicone ne da aka gyara. A matsayin wani abu mai kyau.ingantaccen mai rarraba jini, yana bayar da mafita ga ƙalubalen da ke tattare da cimma ingantaccen yaɗuwa, kuma sakamakon haka, ingantaccen tsaron wuta.

Ana ba da shawarar SILIKE SILIMER 6150 don amfani da shiwatsawar launukan halitta da na inorganic da kuma abubuwan cikawa, masu hana harshen wuta a cikin thermoplastic masterbatch, TPE, TPU, sauran thermoplastic elastomers, da aikace-aikacen mahadi. Ana iya amfani da shi a cikin nau'ikan polymers na thermoplastic ciki har da polyethylene, polypropylene, polystyrene, ABS, da PVC.

SILIKE SILIMER 6150, Babban fa'idar mahaɗan hana harshen wuta

1. Inganta watsawar mai hana harshen wuta

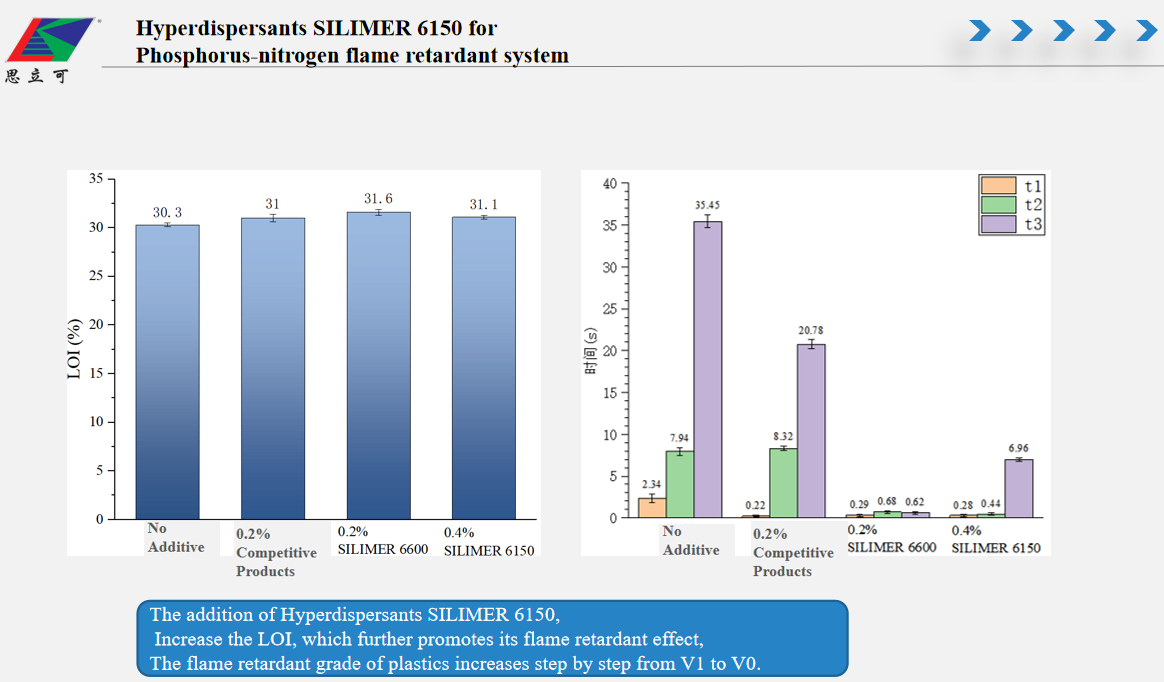

1) Ana iya amfani da SILIKE SILIMER 6150 tare da babban tsarin phosphorus-nitrogen mai hana harshen wuta, yana inganta tasirin hana harshen wuta na mai hana harshen wuta yadda ya kamata. Ƙara LOI, mai hana harshen wuta na robobi yana ƙaruwa mataki-mataki daga V1 zuwa V0.

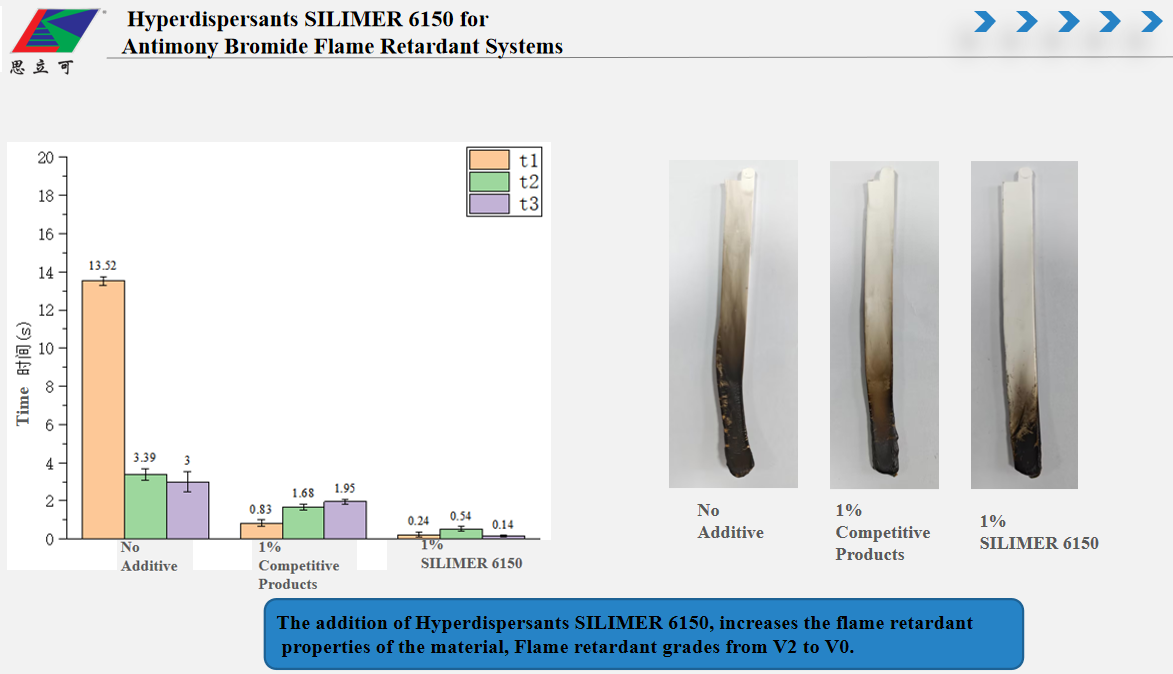

2) SILIKE SILIMER 6150 kuma yana da kyakkyawan haɗin gwiwa tsakanin masu hana harshen wuta da Antimony Bromide Flame Retardant Systems, masu hana harshen wuta daga V2 zuwa V0.

2. Inganta sheƙi da santsi na saman samfura (ƙarancin COF)

3. Inganta yawan narkewar ruwa da kuma watsawar abubuwan cikawa, ingantaccen sakin mold da kuma ingantaccen sarrafawa

4. Inganta ƙarfin launi, babu wani mummunan tasiri ga halayen injiniya.

Tuntuɓi SILIKE don ganin yadda SILIMER 6150 Hyperdispersant zai iya taimaka wa masu tsarawa wajen ƙirƙirar sabbin sinadarai masu hana harshen wuta da kuma thermoplastics!

Lokacin Saƙo: Oktoba-23-2023