Nau'in filastik mai kama da thermoplastic wanda aka yi da resin polymer wanda ke zama ruwa mai kama da juna lokacin da aka dumama shi kuma ya yi tauri lokacin da aka sanyaya shi. Duk da haka, lokacin da aka daskare shi, thermoplastic yana kama da gilashi kuma yana iya karyewa. Waɗannan halaye, waɗanda suka ba da sunan kayan, ana iya juyawa. Wato, ana iya sake dumama shi, sake siffanta shi, kuma a daskare shi akai-akai. Wannan ingancin kuma yana sa thermoplastics su sake yin amfani da su. Kuma, thermoplastics sune nau'in filastik da aka fi amfani da su tare da Polyethelene (gami da HDPE, LDPE da LLDPE), Polypropylene (PP), Polyvinyl Chloride (PVC), da Polyethylene terephthalate (PET) sune mafi yawan amfani. Sauran ƙungiyoyin thermoplastics sune Acrylonitrile Butadiene Styrene (ABS), Ethylene Vinyl Acetate (EVA), Nylons (Polyamides) PA, Polystyrene (PS), Polymethyl Methacrylate (PMMA, acrylic), Thermoplastic Elastomers TPU TPE, TPR…

Kwanan nan, an fi mai da hankali kan ilmin sunadarai masu kore tare da saurin ci gaban tattalin arzikin duniya, haɓaka wayar da kan jama'a game da kare muhalli, da kuma buƙatar kowane fanni ga inganci da aikin sassan da sassan.

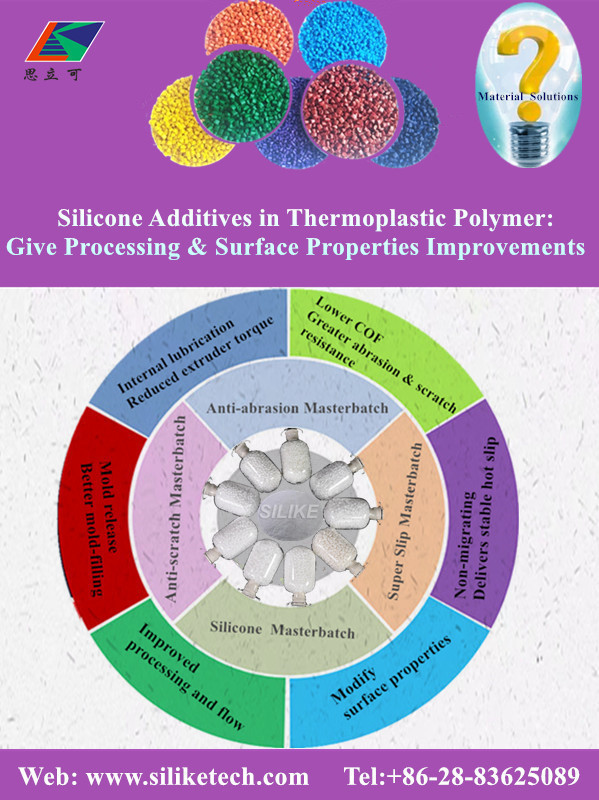

An tabbatar da cewa masana'antun thermoplastics suna neman inganta yawan fitarwa, cimma daidaiton cika mold, ingancin saman da ya dace, ƙarancin amfani da wutar lantarki, da kuma taimakawa wajen rage farashin makamashi, duk ba tare da yin gyare-gyare ga kayan aikin sarrafawa na gargajiya ba, za su iya amfana dagaƙarin siliconedon samar da kyawawan abubuwan saman da suka dace, gami da ƙarancin COF, juriyar gogewa da karce, jin hannu, da juriyar tabo, da kuma taimakawa ƙoƙarin samfurin su na samar da tattalin arziki mai zagaye.

Fasaha mai ci gaba a fannin ƙarin silicone ita ce amfani da nauyin ƙwayoyin halitta mai matuƙar girma (UHMW)Polymer na silicone (PDMS)a cikin nau'ikan masu ɗaukar thermoplastic daban-daban ko resins masu aiki, waɗanda ke haɗa ingantaccen sarrafawa tare da farashi mai araha.

Kamfanin SILIKE TECHƙarin silicone,ko daibabban batch ɗin siliconeƙananan ƙwayoyi kofoda na silicone,suna da sauƙin ciyarwa, ko haɗawa, cikin robobi yayin haɗawa, fitarwa, ko ƙera allura don inganta yawan aiki don cimma saurin sarrafawa mai sauri, kawar da matsala ga tarin extruders, da haɓaka ingancin saman.

Lokacin Saƙo: Yuni-29-2022