Polycarbonate (PC) yana ɗaya daga cikin na'urorin thermoplastics na injiniya mafi amfani da ake amfani da su a cikin ruwan tabarau na motoci, na'urorin lantarki na masu amfani, kayan ido, da kayan kariya. Ƙarfin tasirinsa mai girma, haske mai haske, da kwanciyar hankali na girma sun sa ya dace da aikace-aikacen da ke buƙatar kulawa. Duk da haka, sanannen koma-baya na PC shine ƙarancin taurin saman sa, wanda ke haifar da rashin ƙarfin karce da juriya ga lalacewa - musamman a lokacin da ake yawan haɗuwa ko yanayin gogewa.

To, ta yaya masana'antun za su iya inganta ƙarfin PC ba tare da yin watsi da bayyananniyar sa ko halayen injina ba? Bari mu bincika hanyoyi daban-daban masu inganci da dabarun da masana'antu suka tabbatar don shawo kan waɗannan ƙalubalen.

Magani: Haɗa haɓaka sarrafawa da gyare-gyaren kadarorin saman tare da fasahar kariya ta zamani.

1. Ƙarin Sinadarai Masu Tushen Silicone: Man shafawa na ciki

Haɗa ƙarin silicone masu aiki sosai, kamar polydimethylsiloxane (PDMS) ko kuma manyan batches na siloxane kamar Dow MB50-001, Wacker GENIOPLAST, da SILIKE Silicone Masterbatch LYSI-413, cikin tsarin polycarbonate (PC) na iya haɓaka aikin kayan sosai. Ta hanyar amfani da waɗannan ƙarin a matakin lodi na 1-3%, za ku iya rage yawan gogayya yadda ya kamata, wanda ke inganta juriyar karce da juriyar lalacewa.

Manyan Fa'idodi: Waɗannan ƙarin silicone, a matsayin ƙarin kayan aiki da masu gyara na PC, ba wai kawai suna kiyaye hasken gani na PC ba, har ma suna ƙara ƙamshi a saman. Wannan yana haifar da raguwar lalacewar saman yayin hulɗa da gogewa, wanda a ƙarshe ke haifar da ingantaccen tsawon rai na samfurin.

Shawara Mai Amfani: Domin tabbatar da ingantaccen aiki, yana da mahimmanci a sami ingantaccen watsawa ta hanyar fitar da dunƙule biyu, wanda ke taimakawa hana rabuwar lokaci kuma yana ƙara fa'idodin ƙarin.

Gabatar da Ƙarin Silikon da aka Yi da SILIKE, Dabaru don Inganta Juriyar Karce da Sawa na Roba na PC

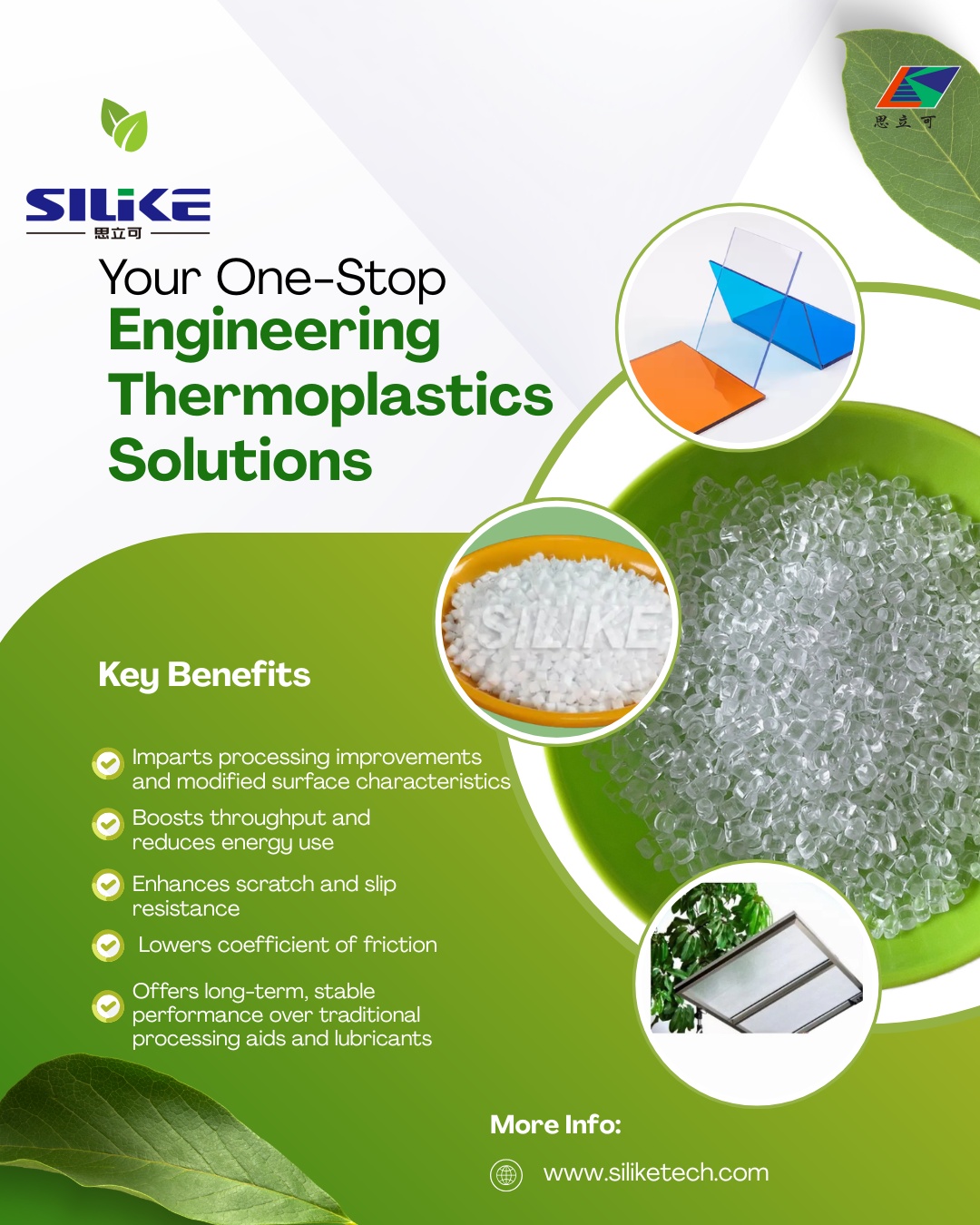

Kamfanin Chengdu SILIKE Technology Co., Ltd babban kamfanin samar da kayayyaki ne na kasar Sinƙarin silicone don robobi da aka gyaraKamfanin yana bayar da mafita masu inganci waɗanda aka tsara don haɓaka aiki da aikin kayan filastik daban-daban. Ɗaya daga cikin fitattun samfuran su shineSilike Silicone Masterbatch LYSI-413,wani tsari mai inganci wanda ya ƙunshi siloxane polymer mai nauyin ƙwayoyin cuta mai girman 25% wanda aka watsa a cikin polycarbonate (PC). Wannan ƙari mai tushen silicone yana da tasiri musamman ga tsarin resin mai jituwa da PC. Yana inganta halayen sarrafawa da ingancin saman ta hanyar haɓaka kwararar resin, sauƙaƙe cikawa da sakin mold, rage ƙarfin fitarwa, rage yawan gogayya, da kuma samar da juriya ga mar da abrasion mafi kyau. Bugu da ƙari, wannan masterbatch mai tushen siloxane yana aiki azaman ƙari mai hana karce, yana mai da shi kyakkyawan mafita don ƙara juriya ga karce na samfuran PC da kuma inganta aikinsu gabaɗaya da dorewa.

2. Rufin Tauri Mai Dauke da Hasken UV Mai Warkewa da Nanotechnology

A shafa fenti mai ƙarfi wanda aka yi da siloxane ko kuma wanda aka yi da kayan halitta da ba na halitta ba (misali, Momentive SilFORT AS4700 ko kuma PPG's DuraShield). Waɗannan fenti suna samun taurin fensir har zuwa 7H-9H, wanda hakan ke inganta juriyar karce sosai.

Haɗa shafaffen nanoparticles (misali, silica ko zirconia) waɗanda za a iya warkar da su ta hanyar UV don ƙara juriya ga gogewa.

Amfani: Yana samar da kariya daga karce, sinadarai, da lalacewar UV, wanda ya dace da aikace-aikacen gani da na mota.

Amfani: Yi amfani da murfin da aka tsoma, feshi, ko murfin kwarara don kauri iri ɗaya (5-10 µm).

3. Ƙarfafa Nanocomposite

Ƙara nanofillers kamar nanosilica, alumina, ko graphene oxide (0.5-2% ta nauyi) zuwa matrix na PC. Waɗannan suna ƙara taurin saman kuma suna inganta juriyar lalacewa ba tare da yin tasiri sosai ga bayyanawa ba idan girman barbashi ya kasance ƙasa da nm 40.

Misali: Bincike ya nuna cewa kashi 1% nanosilica a cikin PC zai iya inganta juriyar gogewar Taber da kashi 20-30%.

Shawara: Yi amfani da masu daidaita (misali, wakilan haɗin silane) don tabbatar da wargajewa iri ɗaya da kuma guje wa haɗuwa.

4. Haɗaɗɗun Kwamfutoci don Daidaita Aiki

Haɗa PC da PMMA (10-20%) don ƙara tauri a saman ko kuma tare da PBT don inganta tauri da juriyar lalacewa. Waɗannan gaurayawan suna daidaita juriyar karce da ƙarfin tasirin PC.

Misali: Hadin PC/PMMA da kashi 15% na PMMA na iya ƙara taurin saman yayin da yake riƙe da haske don aikace-aikacen nuni.

Gargaɗi: Inganta rabon gauraya don guje wa lalata kwanciyar hankali ko tauri na PC.

5. Dabaru Masu Inganta Fuska Mai Kyau

Maganin Jini a Jini: A shafa sinadarin da ke ƙara tururin sinadarai (PECVD) don saka siraran rufi masu tauri kamar silicon oxynitride (SiOxNy) a saman PC. Wannan yana inganta juriyar karce da kuma lalacewar fata.

Tsarin Laser: Ƙirƙiri ƙananan rubutu ko nano-scale akan saman PC don rage yankin hulɗa da yaɗuwar karce, inganta dorewar kyau.

Amfani: Rubutun rubutu zai iya rage yawan gogewa da har zuwa 40% a cikin aikace-aikacen da ke da alaƙa mai yawa.

6. Haɗin ƙari don Haɗin gwiwa

Haɗa ƙarin silicone tare da wasu ƙarin abubuwa masu aiki kamar PTFE (polytetrafluoroethylene) micropowders (0.5-1%) don tasirin haɗin gwiwa. PTFE yana ƙara man shafawa, yayin da silicone yana inganta juriya ga lalacewa.

Misali: Hadin sinadarin silicone mai kashi 2% da PTFE 0.5% na iya rage yawan lalacewa da kashi 25% a aikace-aikacen zamiya.

7. Yanayin Sarrafawa da Aka Inganta:

Yi amfani da haɗakar da aka yi da ƙarfi don watsa ƙarin abubuwa da abubuwan cikawa iri ɗaya. A kiyaye yanayin zafin sarrafa kwamfuta (260-310°C) don guje wa lalacewa.

Yi amfani da dabarun ƙera daidai (misali, ƙera allurar da aka goge da molds) don rage lahani a saman da zai iya haifar da ƙaiƙayi.

An yi amfani da sassan da aka ƙera a cikin annuri a zafin 120-130°C don rage damuwa a cikin jiki, yana inganta aikin lalacewa na dogon lokaci.

Agogon Kirkire-kirkire: Gyaran Kai da Rufin DLC na Tasowa

Fasaha mai tasowa kamar su shafa mai warkar da kai (bisa ga sinadaran polyurethane ko siloxane) da kuma shafa mai kama da lu'u-lu'u (DLC) suna ba da mafita mai dorewa a nan gaba don aikace-aikacen PC masu ɗorewa da kuma masu sauƙin taɓawa. Duk da cewa har yanzu suna da tsada ga samfuran kasuwa, waɗannan fasahohin suna nuna alƙawari a cikin kayan lantarki masu tsada, motoci, da sararin samaniya.

Hanyar da aka ba da shawarar don ingantaccen aiki a fannin injiniyan thermoplastics

Ga masana'antun da ke neman mafita mai amfani, mai sassauƙa don inganta dorewar saman PC, muna ba da shawarar:

1)2% UHMW Silicone Ƙarin don man shafawa na ciki

2) Shafi na UV mai tushen Siloxane + 1% Nano Silica don taurin saman

3) Micro-Texturing ta hanyar Laser Molding don ɓoye scratches

Wannan hanyar mai matakai uku tana samar da daidaiton inganci da farashi, daidaiton sarrafawa, da kuma aiki, wanda hakan ya sa ya dace da kayayyakin da ake fuskanta a kullum kuma suna buƙatar kyawawan halaye na dogon lokaci.

An Tabbatar da Masana'antu

A cewar wani rahoto na 2024 da MarketsandMarkets ta fitar, an yi hasashen cewa kasuwar rufe fuska mai tauri ta duniya za ta wuce dala biliyan 1.3 nan da shekarar 2027, wanda hakan ke haifar da karuwar bukatar robobi masu jure karce a cikin nunin motoci, na'urorin hannu, da ruwan tabarau na gani. Masu tsara kayan aiki da masu hada abubuwa masu amfani da yawa da kuma nano-fillers suna da kyakkyawan matsayi don jagorantar tsarar samfuran PC masu dorewa na gaba.

Shin kuna shirye don haɓaka robobi na injiniyanku kamar PC tare da ingantaccen juriya ga karce da lalacewa?

Bincika SILIKEƙarin robobimafita waɗanda ke haɓaka sarrafawa da halayen saman don biyan buƙatun dorewa.

For further information, please visit our website at www.siliketech.com, or contact us at Tel: +86-28-83625089 or via email at amy.wang@silike.cn. we provide ingantattun hanyoyin sarrafa robobi.

Lokacin Saƙo: Yuli-02-2025