Yadda za a magance matsalolin sarrafawa na masu hana harshen wuta?

Na'urorin rage harshen wuta suna da girma sosai a kasuwa a duk duniya kuma ana amfani da su sosai a masana'antu kamar gini, motoci, kayan lantarki, sararin samaniya, da sauransu. A cewar rahoton binciken kasuwa, kasuwar na'urorin rage harshen wuta ta ci gaba da samun ci gaba mai kyau a cikin 'yan shekarun nan.

Duk da haka, a cikin tsarin samar da na'urorin hana harshen wuta, sau da yawa ana fuskantar waɗannan matsalolin sarrafawa:

Rashin Yaɗuwa Mai Kyau: Masu rage harshen wuta galibi suna wanzuwa a cikin nau'in barbashi ko foda kuma suna da yawan yawa da takamaiman nauyi, wanda hakan ke sa ya yi wuya a warwatse su daidai gwargwado a cikin kayan tushe yayin sarrafawa. Rashin yaɗuwa mara kyau zai haifar da rarrabawar mai rage harshen wuta a cikin kayan, wanda ke shafar tasirin mai rage harshen wuta.

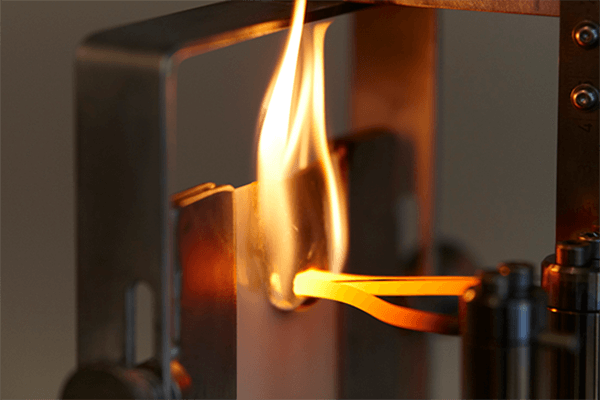

Rashin kwanciyar hankali a yanayin zafi: Wasu na'urorin rage zafi za su ruɓe a yanayin zafi mai yawa ko kuma idan aka fallasa su ga yanayin zafi mai yawa na dogon lokaci, suna rasa tasirinsu na rage zafi har ma suna samar da abubuwa masu cutarwa. Saboda haka, ya zama dole a kula da zafin jiki da lokacin sarrafawa yayin sarrafawa don tabbatar da daidaiton yanayin zafi na na'urorin rage wuta.

Matsalolin daidaito: Akwai yiwuwar samun matsalolin daidaito tsakanin na'urar hana harshen wuta da kayan tushe, wato, kusancin da ke tsakanin su biyun bai isa ya haɗu yadda ya kamata ba. Wannan zai haifar da mummunan wargajewar na'urar hana harshen wuta da kuma rashin gamsuwa da na'urar hana harshen wuta.

Tasiri ga kaddarorin abu: Ƙara yawan abin hana wuta zai iya haifar da raguwar halayen injiniya da na lantarki na kayan, har ma da haifar da lalacewa da nakasa na kayan. Saboda haka, ya zama dole a sarrafa adadin ƙarin gwargwadon takamaiman kayan da halayen abin hana wuta a cikin aikin.

Don shawo kan waɗannan matsalolin injin, ana iya ɗaukar matakai masu zuwa:

Zaɓin hanyar sarrafawa mai dacewa: Dangane da takamaiman kayan aiki da halayen hana harshen wuta, zaɓi hanyar sarrafawa mai dacewa, kamar extrusion, smolding allura, matsi smolding da sauransu. Hanyoyi daban-daban na sarrafawa suna da tasiri daban-daban akan watsawa, dacewa da kwanciyar hankali na thermal na masu hana harshen wuta.

Sarrafa adadin ƙarin kayan aiki: A kula da adadin kayan aikin da aka ƙara da kyau, don guje wa amfani da kayan aikin da ke rage harshen wuta da yawa wanda ke haifar da raguwar aikin kayan.

Inganta watsewar masu hana harshen wuta: Amfani da masu watsawa ko masu gyara saman zai iya inganta watsewar masu hana harshen wuta da kuma ƙara daidaito a cikin kayan.

Zaɓin na'urorin rage wuta masu dacewa: Dangane da takamaiman buƙatun aikace-aikacen, zaɓi na'urorin rage wuta masu dacewa, la'akari da abubuwa kamar kwanciyar hankali na zafi, dacewa da kuma warwatsewarsu.

SILIKE Hyperdispersants – An ƙera shi musamman don watsawa na hana harshen wuta. Wannan jerin samfuran ya dace da resin thermoplastic na gama gari, TPE, TPU da sauran elastomers na thermoplastic. Baya ga masu hana harshen wuta, wannan jerin samfuran ya dace da manyan batches ko kayan da aka riga aka watsa.

- Man shafawa mai kyau na injin

- Ingantaccen ingancin sarrafawa

- Ingantaccen daidaito tsakanin foda da substrate

- Babu ruwan sama, inganta santsi a saman

- Inganta watsawar foda mai hana harshen wuta, hana harshen wuta mai haɗaka

Lokacin Saƙo: Satumba-26-2023