Fim ɗin Marufi Mai Haɗaka abu ne guda biyu ko fiye, bayan ɗaya ko fiye na tsarin laminating na busasshe sannan a haɗa shi, don samar da wani aiki na marufi. Gabaɗaya ana iya raba shi zuwa Layer na tushe, Layer na aiki, da Layer na rufe zafi. Layer na tushe galibi yana taka rawar ado, bugu, da shingen danshi, kamar BOPP, BOPET, BOPA, da sauransu; Layer na aiki galibi yana taka rawar shinge, haske, da sauran ayyuka, kamar VMPET, AL, EVOH, PVDC, da sauransu; Layer ɗin rufe zafi a cikin hulɗa kai tsaye da kayan da aka shirya, daidaitawa, juriya ga shiga ciki, kyakkyawan hatimi, da kuma bayyana gaskiya da sauran ayyuka, kamar LDPE, LLDPE, MLLDPE, CPP, EVA, da sauransu.

Ana iya amfani da aikace-aikacen fim ɗin Marufi na Haɗaɗɗen Rubutu a fannoni daban-daban don marufi na masana'antu, marufi na yau da kullun, marufi na abinci, magani da lafiya, kayan lantarki, sararin samaniya, kimiyya da fasaha, soja, da sauran fannoni. Amma jakunkunan marufi na haɗaɗɗen rubutu suna da matsala gama gari kuma mai wahalar warwarewa, wato, jakunkunan suna da ruwan sama na fari, wanda ke da mummunan tasiri ga masana'antar marufi na haɗaɗɗen rubutu, Magance wannan matsalar ya zama babban fifiko ga masana'antar.

Magance Kalubalen Ruwan Foda Fari a Jakunkunan Marufi na Abinci: Nazarin Misali a Cikin Fim ɗin Marufi Mai Haɗaɗɗen Kaya:

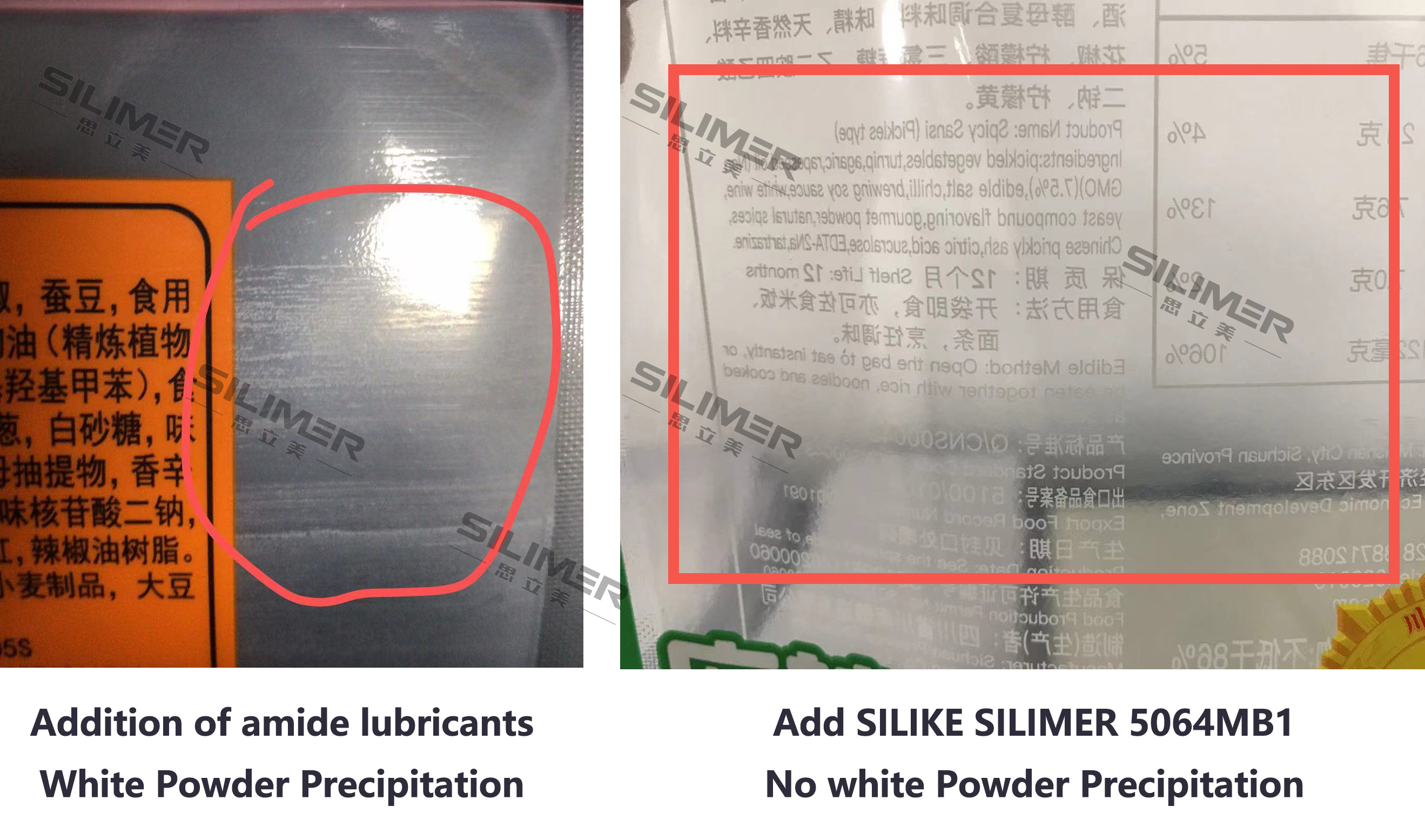

Akwai wani abokin ciniki da ke yin fim ɗin marufi mai haɗaka, ƙarin amide da ya yi amfani da shi a baya ya haifar da zubar farin foda a kan jakunkunan haɗaka, wanda hakan ya shafi sarrafawa da ingancin samfurin ƙarshe. Mafi mahimmanci, ana amfani da jakunkunan marufi masu haɗaka da ya samar don marufi, saboda ruwan farin foda da ke kan jakar zai kasance kai tsaye da abinci, amma kuma yana shafar amincin abinci. Don haka ruwan farin foda da ke kan jakunkunan yana da matukar damuwa ga wannan abokin ciniki. Duk da haka, dalilin shine saboda ƙarancin nauyin ƙwayoyin halitta na ƙarin amide, kuma kwanciyar hankali na zafi ba shi da kyau, tare da canje-canjen lokaci da zafin jiki suna ƙaura zuwa saman fim don ƙarshe samar da foda ko abu mai kama da kakin zuma, wanda ke haifar da zubar farin foda a bayyane akan jakunkunan haɗaka.

Domin magance wannan ƙalubalen, SILIKE ta gabatar daJerin SILIMER na Super-slip MasterbatchMusamman,SILIMER 5064MB1, ababban batch mai zamewa sosaitare da wani tsari na musamman na kwayoyin halitta wanda ya ƙunshi polysiloxanes masu haɗin gwiwa tare da ƙungiyoyin aiki na kwayoyin halitta, ya fito a matsayin mai canza wasa a cikin Fim ɗin Kunshin Haɗaka.

Saboda ƙaramin nauyin ƙwayoyin halitta, ƙarancin kuzarin saman, yana da sauƙin ƙaura zuwa saman filastik da sassa, kuma ƙwayoyin da ke da ƙungiyoyin aiki masu aiki na iya taka rawa wajen ɗaure robobi, don cimma tasirinsauƙin ƙaura ba tare da hazo ba.

Ra'ayin masu sharhi kanSILIMER 5064MB1ya kasance mai kyau, tun lokacin da aka ƙaddamar da shi, ƙara ƙaramin adadinSILIKE SILIMER 5046MB1Zuwa ga matakin rufe zafi, zai iya inganta ingantaccen hana toshewa da santsi na fim ɗin, kuma man shafawa yayin sarrafawa na iya rage yawan tasirin gogayya mai ƙarfi da tsayayyen yanayin saman fim ɗin, yana sa saman fim ɗin ya yi laushi, yana kawar da ruwan farin foda a saman jakunkunan marufi masu sassauƙa da ake amfani da su a cikin marufi na abinci. Wani abin da ya fi jan hankali shi ne saman fim ɗin yana da ingantaccen aiki mai santsi a ƙarƙashin yanayin zafi mai yawa ko kafin da bayan warkewa, ba ya shafar bugawa, rufe zafi, watsawa, ko hazo.

SILIKE Super-slip masterbatch SILIMER 5064MB1Ana amfani da shi galibi a cikin fina-finan BOPE, fina-finan CPE, aikace-aikacen fim mai faɗi, da sauran samfuran fim ɗin marufi masu haɗawa.

Ga masana'antun da ke fuskantar irin wannan matsala tare da fim ɗin marufi mai haɗawa don jakunkunan marufi na abinci, SILIKE yana ba da shawarar gwadawaSILIMER 5064MB1don gwajin samfurin.

Wannan sabon abuBabban wasan kwaikwayo mai ban mamakiba wai kawai magance matsalar ruwan sama na farin foda ba, har ma yana ƙara inganta aikin sarrafawa gabaɗaya, yana rage lahani da farashi.

Jefa tsohon abin da ake ƙarawa a cikin amide ɗinka, sannan ka tuntuɓi SILIKE don gano yadda wannan zai yi aiki.sabuwar mafita ta Super-slip Masterbatchzai iya haɓaka inganci da amincin samfuran fim ɗin marufi na haɗin gwiwa!

Lokacin Saƙo: Disamba-13-2023