Shin kuna fama da watsawar na'urar hana wuta mara daidaito a cikin kayayyakin polymer ɗinku? Rashin rarrabawa mara kyau ba wai kawai yana raunana aikin tsaron wuta ba, har ma yana lalata halayen injiniya kuma yana haɓaka farashi. Me zai faru idan za ku iya magance waɗannan matsalolin tare da na'urorin watsawa masu dacewa? A cikin wannan labarin, za mu binciki yaddaSabbin fasahar watsawazai iya canza tsarin hana harshen wuta—tabbatar da wargajewar iri ɗaya, haɓaka juriyar wuta, da kuma daidaita ingancin sarrafawa don samun sakamako mai kyau.

Me Yasa Watsawa Mai Rage Wuta Yana Da Muhimmanci Ga Masu Kera Polymer?

Matsala ta 1: Watsawar da ba ta daidaita ba ta hana harshen wuta yana haifar da damuwa game da tsaro

Idan ƙarin abubuwan hana harshen wuta ba su warwatse daidai gwargwado ba, za ka iya fuskantar matsalolin tsaro, kamar:

Raunanawar Juriyar Wuta: Ƙananan Iyakancewar Iskar Oxygen (LOI) da kuma rashin tabbas na ƙimar UL94.

Matsalolin Ingancin Fuskar Gida: Tsarukan laushi da ƙarancin sheƙi suna shafar kyawun fuska da dorewa.

Rage Ƙarfin Inji: Ƙara karyewa da matsalolin kwarara a cikin samfurin ƙarshe.

Karin Kuɗin Samarwa: Sake yin aiki, ɓatar da kayan aiki, da kuma tsawon lokacin sarrafawa.

Matsala ta 2: Iyakokin Aiki tare da Tsarin Gargajiya na Masu Hana Wuta

Hanyoyin gargajiya na watsawa na hana harshen wuta sau da yawa suna fama da tarin ƙwayoyin cuta, wanda ke haifar da rashin daidaiton aiki. Wannan na iya shafar ikon ku na cika buƙatun ƙa'idoji da kuma kawo cikas ga aikin samfurin ƙarshe a aikace-aikacen duniya ta ainihi.

Mafita ta Ƙarshe Mai Rage Wuta:SILIMER 6600 Hyperdispersant Inganta FR Watsawa a cikin Polymers

SILIKE SILIMER 6600 wani ƙari ne na polymer wanda aka yi da silicone, idan aka yi amfani da shi azaman mai wargazawa, wanda ke magance ƙalubalen wargazawa da masana'antun polymer ke fuskanta. Tsarinsa na musamman na triblock copolymer - wanda ya haɗa polysiloxane, ƙungiyoyin polar, da dogayen rukunin sarkar carbon - yana ba da sakamako mai ban mamaki. Yana da aikace-aikace iri-iri, gami da wargazawar hana harshen wuta, wargazawar launi, da wargazawar cikawa.

Ta Yaya Silicone Hyperdispersant na SILIMER 6600 Ke Aiki?

1. Ingantaccen Yaɗuwar Masu Rage Wuta: Ƙungiyoyin Polar a cikin haɗin hyperdispersant tare da masu rage wuta, suna tabbatar da cewa warwatsewar ta kasance mai daidaito, iri ɗaya a cikin matrix na polymer.

2. Yana Hana Sake Haɗuwa: Sassan Polysiloxane suna kiyaye warwatsewar da ta dace koda a ƙarƙashin yankewar injina, yana tabbatar da cewa na'urar hana harshen wuta ta kasance a ko'ina.

3. Ƙara dacewa da Kayan Tushe: Dogayen sarƙoƙin carbon suna tabbatar da dacewa da tsarin polyolefin, suna hana ƙaura ko fitar da abubuwan hana wuta yayin sarrafawa.

Manyan Fa'idodin Fasahar Dispersant SILIMER 6600 a cikin Aikace-aikacen Mai Rage Wuta:

1. Yana inganta watsawar hana harshen wuta a cikin kayan tushe, yana haɓaka aikin hana harshen wuta.

2. Yana inganta halayen injiniya ta hanyar tabbatar da cewa an rarraba na'urorin hana harshen wuta iri ɗaya.

3. Yana hana sake taruwa da ƙwayoyin da ke hana harshen wuta, yana kiyaye wargajewar da ta dace.

4. Kyakkyawan jituwa da tsarin polyolefin, rage ƙaura ko fitar da iska.

5. Yana aiki a matsayin taimakon sarrafawa, yana inganta man shafawa da ingancin samarwa.

Kimanta Aiki na Mai Rarraba SILIMER 6600 a cikin Tsarin Mai Rage Wuta

1. Gwaji

Phosphorus-Nitrogen Intumescent Flame Retardant

Hanyar Shiri: Maganin hana harshen wuta da aka yi wa magani da na'urar watsawa → An haɗa shi da resin → Allura da aka ƙera zuwa samfuran gwaji → Gwajin aiki

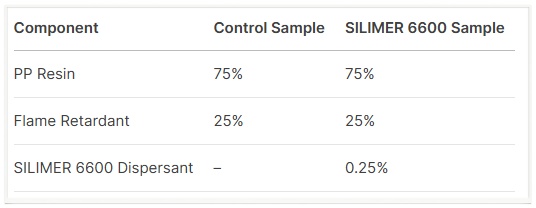

2. Tsarin

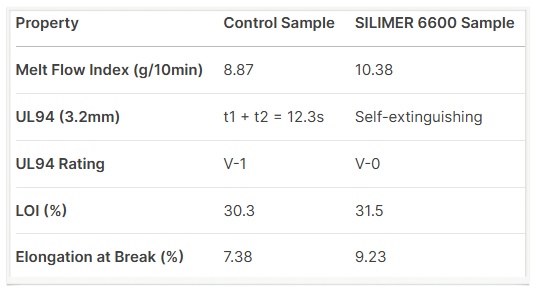

3. Sakamakon Gwaji

4. Kammalawa

Ingantaccen Rage Wutar Lantarki: Samfurin da aka yi wa magani ya sami ƙimar UL94 V-0 (idan aka kwatanta da V-1 don sarrafawa) da kuma saurin ɗabi'ar kashe kansa.

Ingantaccen Tsarin Sarrafawa: Babban ma'aunin kwararar narkewa yana nuna ingantaccen tsarin sarrafawa.

Rike Kadarorin Inji: Ƙara tsawon lokaci a lokacin hutu yana tabbatar da ingantaccen wargajewa ba tare da rage ƙarfin kayan ba.

Idan kuna fuskantar matsalolin watsawa na hana harshen wuta, ƙarancin ƙimar UL94, ko ƙalubalen sarrafawa, tuntuɓi SILIKE don samun na'urar watsawa mai aiki da yawa. Ba wai kawai tana ba da mafita ta SILIMER 6600 don masterbatch na hana harshen wuta ba, har ma tana ba da fasahar watsawa ta zamani da aka inganta don launuka da cikawa.

(Learn More: www.siliketech.com | Email: amy.wang@silike.cn)

Lokacin Saƙo: Mayu-28-2025