A kasuwar marufi ta zamani, masana'antun suna fuskantar wajibcin inganta aikin fina-finan filastik ɗinsu. Wannan burin galibi yana fuskantar ƙalubale kamar toshe fim yayin sarrafawa da sarrafawa, wanda zai iya kawo cikas ga layukan samarwa da rage ingancin aiki. Bugu da ƙari, rashin isasshen abubuwan zamewa na iya haifar da matsaloli gami da rashin ingantaccen sarrafawa, mannewa, da marufi mara daidaito, wanda hakan ke shafar ingancin kyau da aikin samfurin ƙarshe.

Dabaru Don Magance Kalubalen Samar da Fim ɗin Roba

Muhimmancin Magungunan Zamewa da Kariya Daga Kuraje a Fina-finan Roba

Ma'aikatan zamewa da hana toshewa muhimman abubuwan ƙari ne da ake amfani da su wajen ƙera fina-finan filastik. Waɗannan ma'aikatan suna da matuƙar muhimmanci wajen haɓaka aiki, sarrafawa, da sarrafa halayen fina-finai, musamman a aikace-aikacen marufi. Sashe na gaba yana ba da taƙaitaccen bayani game da ayyukansu kuma yana nuna mahimmancin su a cikin tsarin samarwa.

Wakilan Zamewa

Sinadaran zamewa su ne ƙarin abubuwa waɗanda ke rage gogayya tsakanin layukan fim ɗin filastik ko tsakanin fim ɗin da sauran saman. Suna taimakawa wajen inganta sauƙin sarrafawa da sarrafawa na fim ɗin, musamman a lokacin ƙera shi, jigilar sa, da amfani da shi.

Ayyuka da Fa'idodin Sinadaran Zamewa:

Rage Daidaiton Juriya (COF): Babban aikin sinadaran zamewa shine rage yawan juriya (COF) tsakanin saman fim ɗin filastik. Wannan yana sauƙaƙa sarrafa fim ɗin, musamman a cikin hanyoyin sarrafa kansa kamar layukan marufi masu sauri.

Ingantaccen Tsarin Aiki: Ta hanyar rage gogayya, abubuwan zamewa suna hana fim ɗin mannewa a kan na'urori masu juyawa ko injina yayin aiwatar da fitarwa ko tsarin thermoforming, ta haka ne inganta ingancin samarwa gaba ɗaya.

Ingantaccen Aiki: Abubuwan zamewa suna ƙara ƙarfin fim ɗin na zamewa a saman saman, wanda hakan ke sauƙaƙa buɗe marufi, rage yuwuwar mannewa, da kuma inganta dorewar marufin.

Abubuwan Zamewa Na Yau Da Kullum:

1. Fatty Acid Amides (misali, Erucamide, Oleamide): Waɗannan su ne sinadaran zamewa da aka fi amfani da su. Suna ƙaura zuwa saman fim ɗin kuma suna rage gogayya a saman.

2. Haɗaɗɗun Silikon: Ana amfani da sinadaran zamiya na Silikon sau da yawa don inganta halayen zamiya kuma suna ba da babban matakin aiki a aikace-aikace waɗanda ke buƙatar ƙarin inganci.

Magungunan hana toshewa

Ana ƙara magungunan hana toshewa don hana mannewa ko mannewa na yadudduka na filastik a lokacin ajiya, sarrafawa, ko jigilar kaya. Ba tare da magungunan hana toshewa ba, fim ɗin zai iya mannewa tare, wanda ke haifar da matsala wajen sassautawa ko marufi.

Ayyuka da Fa'idodin Magungunan Hana Kutse:

Rigakafin Mannewa a Layer: Babban aikin magungunan hana toshewa shine ƙirƙirar ƙananan wurare ko saman da ba su da ƙarfi a kan fim ɗin, wanda ke hana kowane Layer mannewa tare.

Ingantaccen Gyaran Fim: A cikin birgima na fim, magungunan hana toshewa suna taimakawa wajen kiyaye ingancin yadudduka na fim yayin hutawa, wanda hakan ke sauƙaƙa wa injunan marufi ta atomatik su iya sarrafa kayan.

Rage Mannewa a Sama: Magungunan hana toshewa suna tabbatar da cewa ana iya tara fina-finai ko kuma a jika su ba tare da haifar da matsaloli kamar toshe fim ko niƙa ba, wanda zai iya haifar da rashin lokacin samarwa ko ɓatar da kayan aiki.

Magungunan Antiblock na gama gari:

1. Silica (SiO₂): Silica ita ce maganin hana toshewa da aka fi amfani da shi a cikin fina-finan filastik. Yana samar da hanya mai inganci don rage hulɗar saman tsakanin layuka.

2. Talc: Talc wani maganin hana toshewa ne da ake amfani da shi sosai. Yana aiki ta hanyar ƙara tsatsa a saman fata da kuma hana fina-finai mannewa.

3. Calcium Carbonate (CaCO₃): A wasu lokutan ana amfani da Calcium carbonate a matsayin maganin hana toshewa, musamman a fina-finai inda ake fifita rage farashi, kodayake ba shi da tasiri kamar silica a wasu lokuta.

Haɗa Magungunan Zamewa da Maganin Hana Kutse

A cikin fina-finai da yawa, ana amfani da magungunan zamewa da na hana toshewa tare don inganta aikin fim. Waɗannan wakilai suna ba da fa'idodi masu dacewa, musamman a aikace-aikacen inda fina-finai ke fuskantar sauƙin sarrafawa ko kuma suna buƙatar tsayayya da mannewa tsakanin layuka. Haɗin da ya dace yana tabbatar da cewa fim ɗin yana da sauƙin sarrafawa kuma yana da sauƙin sarrafawa, yayin da kuma yake kiyaye aikinsa da amincinsa.

Manyan Fa'idodin Haɗa Magungunan Zamewa da Maganin Hana Kutse:

Sarrafawa Mai Sanyi: Ta hanyar tabbatar da cewa fim ɗin yana tafiya cikin sauƙi ta hanyar samarwa da sarrafa shi, duka abubuwan zamewa da hana toshewa suna rage matsin lamba na inji akan fim ɗin.

Ingantaccen Ingancin Samfura: Tare da waɗannan wakilai, samfurin ƙarshe zai sami ingantaccen haske na gani, rage mannewa daga fim zuwa fim, da kuma sauƙin sarrafawa, wanda yake da mahimmanci a aikace-aikacen marufi.

Ingantaccen Amfani da Kuɗi: Haɗin da ya dace na zamewa da hana toshewa na iya rage sharar kayan aiki, inganta ingancin samarwa, da kuma haɓaka aikin samfurin fim na ƙarshe.

Domin mayar da martani ga karuwar bukatar ingantattun hanyoyin samar da fina-finai wadanda ke bayar da man shafawa mai zafi sosai, juriya ga ruwan sama, ingantaccen hana toshewa, da kuma karancin tasiri ga bugawa, Silike ya samar da jerin kayayyaki guda biyar daban-daban wadanda aka tsara don biyan bukatun masana'antar fina-finai masu tasowa.

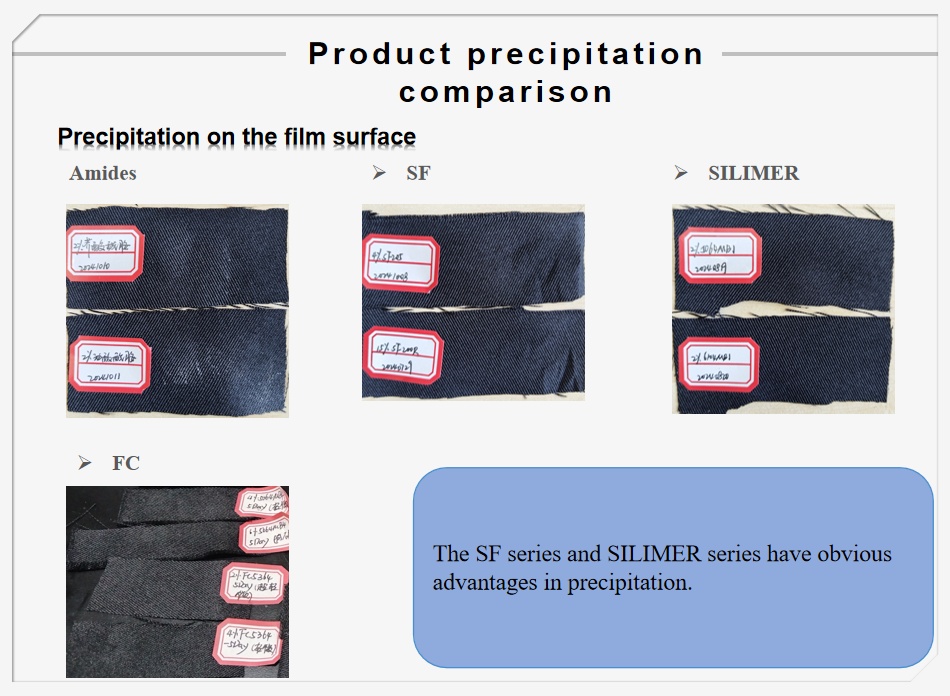

1. SILIKEBabban tsarin SILIMER Series mai ban mamaki da kuma hana toshewa:Wannan fasaha ta zamanibabban zamewa da kuma hana toshewa na babban tsariAn ƙera shi sosai don fina-finan filastik. Ta hanyar haɗa wani polymer na silicone da aka gyara, jerin SILIMER suna magance ƙalubalen da ake fuskanta da suka haɗa da sinadarai masu laushi na gargajiya, kamar ruwan sama da mannewa mai zafi. Wannan mafita mai ƙirƙira yana ƙara haɓaka halayen hana toshewa da santsi sosai, wanda ke rage yawan gogayya mai tsauri da ƙarfi yayin sarrafawa. Sakamakon haka, saman fim ɗin yana samun santsi mai ban mamaki. Bugu da ƙari, SILIMER yana kula da kyakkyawan jituwa da resins na matrix, yana tabbatar da babu ruwan sama ko mannewa yayin da yake kiyaye bayyananniya na fim ɗin. Ana amfani da shi sosai wajen samar da fina-finan polypropylene (PP) da polyethylene (PE).

2.Jerin Silike SFSuper Slip Masterbatch: An tsara shi musamman don aikace-aikacen fim ɗin filastik, wannan jerin yana da polymer na silicone da aka gyara musamman a matsayin sinadarin aiki. Jerin SF yana magance manyan ƙuntatawa da aka fuskanta tare da abubuwan zamewa na gargajiya, kamar ci gaba da hazo daga saman fim ɗin, raguwar aikin zamewa akan lokaci, da ƙamshi mara kyau a yanayin zafi mai yawa. Tare da halayen zamewa da hana toshewa, jerin SF yana riƙe da ƙarancin coefficient na gogayya (COF) yayin da yake hana duk wani ruwan sama. Wannan ya sa ya zama zaɓi mafi kyau don samar da fina-finan BOPP, fina-finan CPP, fina-finan TPU, fina-finan EVA, fina-finan siminti, da kuma rufin extrusion.

3. Babban rukunin SILIKE FA Series na hana toshewa:Wannan sabuwar dabarar hana toshewa ta ƙunshi sinadarai guda uku masu aiki: silica, aluminosilicate, da PMMA. An ƙera ta musamman don dacewa da nau'ikan fina-finai iri-iri, gami da fina-finan BOPP, fina-finan CPP, da fina-finan da aka tsara musamman. Jerin FA yana ƙara haɓaka halayen hana toshewa da santsi, godiya ga tsarinsa na musamman wanda ke tabbatar da daidaito mai kyau.

4. Silike FC Series:

- Mahimman Sifofi: Sufuri mai santsi, ƙarancin fitar da iska

- Babban Sinadaran Aiki: Copolymer polysiloxane (silicon wax) da amide

5. Jerin SILIKE FSE:

- Mahimman fasaloli: Santsi mai kyau, ingantaccen farashi

- Babban Sinadarin Aiki: amide mai tsarki sosai

Shin kana fuskantar ƙalubale game da toshewar fim ko kuma magance rashin inganci a fannin shirya fina-finanka?

Gano yadda manyan wakilanmu na zamewa da hana toshewa za su iya inganta aikin fina-finan filastik ɗinku sosai, ta hanyar tabbatar da ingantaccen sarrafawa da inganta ingancin samfur.

Daga rage gogayya zuwa hana mannewa a kan yadudduka da kuma rage ruwan sama a kan foda, hanyoyinmu - kamar SILIKE SILIMER da SF Series - suna ba da fa'idodi marasa misaltuwa ga layukan marufi masu sauri, suna sa samar da ku ya fi inganci da kuma inganci.

Bugu da ƙari, Silike ta himmatu wajen dorewa tare da nau'ikan PPA na PFAS-Free don aikace-aikacen fim. Waɗannan zaɓuɓɓukan da ba su da PFAS ba kawai suna haɓaka aiki ba, har ma suna tallafawa ayyukan da suka dace da muhalli a cikin samar da fina-finai. Ta hanyar waɗannan hanyoyin samar da sabbin hanyoyin, Silike ta himmatu wajen taimaka wa masana'antar ta ci gaba zuwa ga makoma mai dorewa da inganci.

Idan kuna neman inganta aikin samar da fim ɗin filastik, SILIKE yana ba da mafita iri-iri. Ko kuna buƙatarsa.ƙarin zamewa don fina-finan filastik, masu zamewa don fina-finan polyethylene, koingantattun wakilai masu zamewa masu zafi waɗanda ba sa ƙaura,Muna da samfuran da suka dace da buƙatunku. An ƙera ƙarin abubuwan da ba sa ƙaura da kuma hana toshewa don haɓaka aiki da kuma inganta tsarin kera ku.

Muna gayyatarku da ku tuntuɓi SILIKE don tattaunawa, inda za mu iya tattauna yadda za mu yi mu'amala da ku.manyan zamewa da kuma manyan batches na hana toshewa can contribute to achieving outstanding results in your plastic film production. Email us at amy.wang@silike.cn or visit our website at www.siliketech.com to learn more.

Lokacin Saƙo: Afrilu-30-2025