Gabatarwa ga Polyolefins da Fitar da Fim

Polyolefins, wani nau'in kayan macromolecular da aka haɗa daga monomers na olefin kamar ethylene da propylene, sune robobi da aka fi samarwa da amfani da su a duniya. Yaɗuwarsu ta samo asali ne daga haɗakar halaye na musamman, gami da ƙarancin farashi, ingantaccen sarrafawa, ingantaccen kwanciyar hankali na sinadarai, da halaye na zahiri da aka daidaita. Daga cikin nau'ikan aikace-aikacen polyolefins daban-daban, kayayyakin fim suna da matsayi mai mahimmanci, suna yin ayyuka masu mahimmanci a cikin marufi na abinci, murfin noma, marufi na masana'antu, kayayyakin likita da tsafta, da kayan masarufi na yau da kullun. Mafi yawan resins na polyolefin da ake amfani da su don samar da fim sun haɗa da polyethylene (PE) - wanda ya ƙunshi Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), da High-Density Polyethylene (HDPE) - da polypropylene (PP).

Ana amfani da fasahar fitar da fina-finan polyolefin wajen kera fina-finan, inda ake amfani da fasahar fitar da fina-finai ta Blown Film Extrusion da kuma Fitar da fina-finan Cast Film Extrusion a matsayin manyan hanyoyin aiwatarwa.

1. Tsarin Fim ɗin da Aka Busa

Fitar da fim ɗin da aka hura yana ɗaya daga cikin hanyoyin da aka fi amfani da su wajen samar da fina-finan polyolefin. Babban ƙa'idar ta ƙunshi fitar da polymer mai narkewa a tsaye ta sama ta cikin wani abin rufe fuska mai siffar annular, wanda ke samar da wani bututu mai sirara mai katanga. Daga nan, ana shigar da iska mai matsewa cikin cikin wannan parison, wanda ke sa shi ya hura zuwa wani kumfa mai diamita mafi girma fiye da na mutun. Yayin da kumfa ke hawa, ana sanyaya shi da ƙarfi kuma yana ƙarfafa shi ta hanyar zoben iska na waje. Sannan ana ruguza kumfa mai sanyaya ta hanyar jerin abubuwan birgima (sau da yawa ta hanyar firam mai rugujewa ko firam ɗin A) sannan a zana shi ta hanyar abubuwan birgima kafin a naɗe shi a kan birgima. Tsarin fim ɗin da aka hura yawanci yana samar da fina-finai masu yanayin biaxial, ma'ana suna nuna daidaito mai kyau na halayen injiniya a cikin alkiblar injin (MD) da alkiblar juyawa (TD), kamar ƙarfin tensile, juriyar tsagewa, da ƙarfin tasiri. Ana iya sarrafa kauri fim da halayen injiniya ta hanyar daidaita rabon busawa (BUR - rabo na diamita kumfa zuwa diamita) da rabon ja-ƙasa (DDR - rabo na saurin ɗauka zuwa saurin fitarwa).

2. Tsarin Fim ɗin 'Yan Wasan Kwaikwayo

Fitar da fim ɗin siminti wani muhimmin tsari ne na samarwa ga fina-finan polyolefin, wanda ya dace musamman don ƙera fina-finan da ke buƙatar ingantattun halayen gani (misali, haske mai yawa, sheƙi mai yawa) da kuma daidaito mai kyau na kauri. A cikin wannan tsari, ana fitar da polymer mai narkewa a kwance ta hanyar T-die mai lebur, wanda ke samar da yanar gizo mai narke iri ɗaya. Sannan ana zana wannan yanar gizon cikin sauri akan saman ɗaya ko fiye na naɗewar sanyi mai sauri, a cikin ciki. Narkewar tana taurare da sauri lokacin da ta taɓa saman naɗewar sanyi. Fina-finan siminti gabaɗaya suna da kyawawan halayen gani, jin laushi, da kuma kyakkyawan rufe zafi. Daidaitaccen iko akan gibin lebe na die, zafin naɗewar sanyi, da saurin juyawa yana ba da damar daidaita kauri fim da ingancin saman.

Manyan Kalubalen Fitar da Fim ɗin Polyolefin guda 6

Duk da girman fasahar fitar da iskar gas, masana'antun kan fuskanci matsaloli iri-iri wajen samar da fina-finan polyolefin, musamman lokacin da ake ƙoƙarin samar da kayayyaki masu inganci, inganci, siraran ma'auni, da kuma lokacin amfani da sabbin resins masu aiki mai yawa. Waɗannan matsalolin ba wai kawai suna shafar daidaiton samarwa ba, har ma suna shafar ingancin samfurin ƙarshe da farashinsa. Manyan ƙalubalen sun haɗa da:

1. Karyewar Narkewa (Sharkskin): Wannan yana ɗaya daga cikin lahani da aka fi samu a cikin fitar da fim ɗin polyolefin. A macroscopic, yana bayyana a matsayin ripples na lokaci-lokaci ko kuma wani wuri mai tsauri mara tsari akan fim ɗin, ko kuma a cikin mawuyacin hali, murƙushewa mai ƙarfi. Karyewar narkewa galibi tana faruwa ne lokacin da ƙimar yankewar narkewar polymer da ke fitowa daga injin ya wuce ƙima mai mahimmanci, wanda ke haifar da zamewar sanda tsakanin bangon injin da narkewar babban abu, ko kuma lokacin da matsin lamba mai tsawo a wurin fitar da injin ya wuce ƙarfin narkewa. Wannan lahani yana lalata halayen gani na fim ɗin (bayyananne, sheƙi), santsi na saman, kuma yana iya lalata halayen injina da shinge.

2. Die Drool / Die Ginawa: Wannan yana nufin tarin samfuran lalata polymer a hankali, ƙananan juzu'in nauyin kwayoyin halitta, ƙarin abubuwa marasa kyau (misali, pigments, antistatic agents, slip agents), ko gels daga resin a gefunan lebe ko a cikin ramin die. Waɗannan ma'adanai na iya cirewa yayin samarwa, suna gurɓata saman fim ɗin kuma suna haifar da lahani kamar gels, streaks, ko tarkace, don haka suna shafar bayyanar da ingancin samfurin. A cikin mawuyacin hali, tarin die na iya toshe hanyar fita daga die, wanda ke haifar da bambance-bambancen ma'auni, yagewar fim, da kuma tilasta rufe layin samarwa don tsaftace die, wanda ke haifar da asara mai yawa a cikin ingancin samarwa da asarar kayan.

3. Matsi Mai Yawa da Canjin Fitarwa: A wasu yanayi, musamman lokacin sarrafa resins masu ƙarfi ko amfani da ƙananan gibin die, matsin lamba a cikin tsarin extrusion (musamman a kan extruder da die) na iya zama mai yawa. Babban matsin lamba ba wai kawai yana ƙara yawan amfani da makamashi ba, har ma yana haifar da haɗari ga tsawon rai na kayan aiki (misali, sukurori, ganga, die) da aminci. Bugu da ƙari, rashin daidaituwar canjin matsin lamba na extrusion yana haifar da bambance-bambancen fitarwa kai tsaye a cikin narkewa, wanda ke haifar da kauri mara tsari na fim.

4. Iyakantaccen Amfani: Domin hana ko rage matsaloli kamar karyewar narkewa da taruwar mutu, masana'antun galibi ana tilasta musu rage saurin sukurori na extruder, wanda hakan ke takaita fitowar layin samarwa. Wannan yana shafar ingancin samarwa da farashin kera kowane sashi na samfurin, wanda hakan ke sa ya zama da wahala a biya buƙatun kasuwa na manyan fina-finai masu rahusa.

5. Wahala a Tsarin Ma'auni: Rashin daidaito a cikin kwararar narkewa, rarrabawar zafin jiki mara iri ɗaya a cikin mashin, da tarin mashin duk na iya taimakawa wajen bambance-bambancen kauri a cikin fim ɗin, duka a juye da kuma a tsayi. Wannan yana shafar aikin sarrafa fim ɗin na gaba da halayen amfani da shi a ƙarshe.

6. Sauyawar Resin Mai Wuya: Lokacin canzawa tsakanin nau'ikan ko matakan resin polyolefin daban-daban, ko kuma lokacin canza launuka masu kyau, sau da yawa yana da wuya a cire kayan da suka rage daga aikin da ya gabata gaba ɗaya daga extruder ɗin da kuma mutu. Wannan yana haifar da haɗuwa da tsoffin kayan aiki, samar da kayan canji, tsawaita lokacin canzawa, da kuma ƙara yawan tarkace.

Waɗannan ƙalubalen sarrafawa na gama gari suna tilasta wa masana'antun fina-finan polyolefin ƙoƙarin haɓaka ingancin samfura da ingancin samarwa, sannan kuma suna kawo cikas ga ɗaukar sabbin kayayyaki da dabarun sarrafawa na zamani. Saboda haka, neman ingantattun mafita don shawo kan waɗannan ƙalubalen yana da matuƙar muhimmanci ga ci gaba mai ɗorewa da lafiya na masana'antar fitar da fina-finan polyolefin.

Maganin Tsarin Fim ɗin Polyolefin: Kayan Aikin Sarrafa Polymer (PPAs)

Kayan Aikin Sarrafa Polymer (PPAs) ƙari ne na aiki waɗanda babban darajarsu ta ta'allaka ne akan inganta halayen rheological na narkewar polymer yayin fitarwa da kuma gyara hulɗarsu da saman kayan aiki, ta haka ne ke shawo kan matsaloli iri-iri na sarrafawa da haɓaka ingancin samarwa da ingancin samfura.

1. PPAs masu tushen fluoropolymer

Tsarin Sinadarai da Halaye: Waɗannan a halin yanzu su ne nau'in PPA da aka fi amfani da su, waɗanda suka girma a fannin fasaha, kuma waɗanda suka fi tasiri. Yawanci homopolymers ne ko copolymers bisa ga monomers na fluoroolefin kamar vinylidene fluoride (VDF), hexafluoropropylene (HFP), da tetrafluoroethylene (TFE), tare da fluoroelastomers sune mafi wakilci. Sarkokin kwayoyin halitta na waɗannan PPAs suna da wadataccen haɗin kuzari mai ƙarfi, ƙarancin polarity na CF, waɗanda ke ba da halaye na musamman na physicochemical: ƙarancin kuzarin saman (kamar polytetrafluoroethylene/Teflon®), kyakkyawan kwanciyar hankali na zafi, da rashin daidaiton sinadarai. Abin mamaki, PPAs na fluoropolymer gabaɗaya suna nuna rashin dacewa da matrices na polyolefin marasa polar (kamar PE, PP). Wannan rashin jituwa muhimmin abu ne don ƙaura mai inganci zuwa saman ƙarfe na mutu, inda suke samar da rufin mai mai ƙarfi.

Kayayyakin da Aka Wakilta: Manyan samfuran da ke cikin kasuwar duniya don PPA na fluoropolymer sun haɗa da jerin Chemours' Viton™ FreeFlow™ da jerin Dynamar™ na 3M, waɗanda ke da babban rabo a kasuwa. Bugu da ƙari, ana amfani da wasu ma'aunin fluoropolymer daga Arkema (jerin Kynar®) da Solvay (Tecnoflon®) azaman, ko kuma mahimman abubuwan haɗin gwiwa a cikin, tsarin PPA.

2. Kayan Aikin Sarrafa Kayan Aiki na Silicone (PPAs)

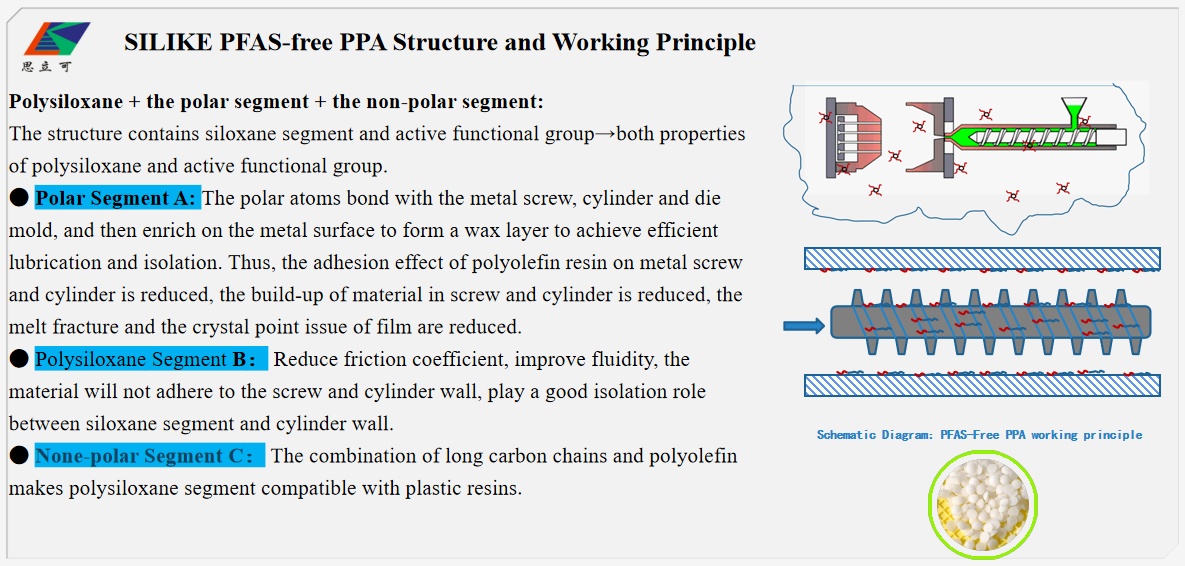

Tsarin Sinadarai da Halaye: Manyan abubuwan da ke aiki a cikin wannan ajin PPA sune polysiloxanes, waɗanda aka fi sani da silicones. Kashin bayan polysiloxane ya ƙunshi ƙwayoyin silicon da oxygen masu canzawa (-Si-O-), tare da ƙungiyoyin halitta (yawanci methyl) da aka haɗa da ƙwayoyin silicon. Wannan tsarin kwayoyin halitta na musamman yana ba da kayan silicone tare da ƙarancin tashin hankali a saman, kyakkyawan kwanciyar hankali na zafi, kyakkyawan sassauci, da kuma halayen da ba su da mannewa ga abubuwa da yawa. Kamar PPAs na fluoropolymer, PPAs na tushen silicone suna aiki ta hanyar ƙaura zuwa saman ƙarfe na kayan aikin sarrafawa don samar da layin mai mai.

Sifofin Aikace-aikacen: Duk da cewa PPAs na fluoropolymer sun mamaye ɓangaren fitar da fim ɗin polyolefin, PPAs na tushen silicone na iya nuna fa'idodi na musamman ko ƙirƙirar tasirin haɗin gwiwa lokacin amfani da su a cikin takamaiman yanayi na aikace-aikace ko tare da haɗin gwiwa tare da takamaiman tsarin resin. Misali, ana iya la'akari da su don aikace-aikacen da ke buƙatar ƙarancin haɗin gwiwa ko inda ake son takamaiman halayen saman samfurin ƙarshe.

Fuskantar Haramcin Fluoropolymer ko Kalubalen Samar da PTFE?

Warware Kalubalen Fitar da Fim ɗin Polyolefin tare da Maganin PPA Kyauta na PFAS-Additattun sinadarai na SILIKE's Fluorine Free Polymer

SILIKE ta ɗauki matakin farko na samfuran jerin SILIMER, tana ba da sabbin dabaruKayan aikin sarrafa polymer marasa PFAS (PPAs)Wannan cikakken layin samfurin yana ɗauke da 100% tsarkakakken PPA mara PFAS,Ƙarin ƙari na PPA polymer mara fluorine, kumaManyan batches na PPA marasa PFAS da kuma marasa fluorine.Ta hanyarkawar da buƙatar ƙarin sinadarin fluorineWaɗannan sarrafa suna taimakawa wajen inganta tsarin kera LLDPE, LDPE, HDPE, mLLDPE, PP, da kuma hanyoyin fitar da fim ɗin polyolefin daban-daban. Suna daidaita da sabbin ƙa'idodin muhalli yayin da suke haɓaka ingancin samarwa, rage lokacin aiki, da inganta ingancin samfur gaba ɗaya. PPAs marasa PFAS na SILIKE suna kawo fa'idodi ga samfurin ƙarshe, gami da kawar da karyewar narkewa (fatar sharks), haɓaka santsi, da ingantaccen ingancin saman.

Idan kuna fama da tasirin hana fluoropolymer ko ƙarancin PTFE a cikin tsarin fitar da polymer ɗinku, SILIKE yana ba da shawararmadadin fluoropolymer PPA/PTFE, Ƙarin abubuwa marasa PFAS don ƙera fina-finaiwaɗanda aka tsara su don biyan buƙatunku, ba tare da buƙatar canje-canjen tsari ba.

Lokacin Saƙo: Mayu-15-2025