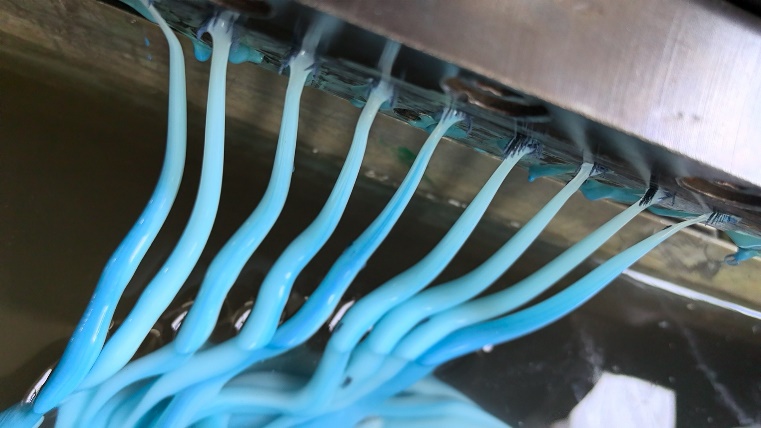

Launi Masterbatch wani sabon nau'in sinadarin launi ne na musamman ga kayan polymer, wanda kuma aka sani da shirye-shiryen fenti. Ya ƙunshi abubuwa uku na asali: fenti ko fenti, mai ɗaukar kaya da ƙari, kuma tarin abubuwa ne da ake samu ta hanyar haɗa wani adadin fenti ko fenti mai ban mamaki ga resin. Ana buƙatar kayan aikin sarrafawa don tabbatar da cewa ana iya watsar da adadi mai yawa na fenti daidai gwargwado, don hana haɗuwa, da kuma guje wa matsaloli kamar narke karyewar nama da Rage tarin manne yayin sarrafawa.

Akwai ƙarin abubuwa da yawa a kasuwa waɗanda za a iya amfani da su don yin amfani da masterbatch na launi, wane irin ƙarin abubuwa ne zai iya magance matsalolin da ke sama?

SILIMERjerinsilicone hyperdispersant, Inganta ingantaccen watsawar foda mai launi iri ɗaya

Matsala ta 1: Alamun kwararar ruwan Masterbatch mai launi, rashin kyawun saman samfurin yayin aiwatar da sarrafa masterbatch.

Matsala ta 2: Tsarin jujjuyawar yana da sauƙin karyewa, fitar da shi ba shi da kyau, kuma ƙimar tacewa ba ta da kyau.

Binciken Dalilai: Babban dalili shi ne girman barbashi na foda mai launi ya yi yawa ko kuma foda mai launi bai warwatse daidai gwargwado ba kuma yana taruwa a wani takamaiman alkibla yayin sarrafawa.

Mafita: SILIKE SILIMER jerin silicone hyperdispersantwani nau'in samfurin polysiloxane ne da aka gyara, wanda zai iya inganta daidaito tsakanin foda mai launi da kuma substrate na resin, yana haɓaka watsawar foda mai launi mai inganci da daidaito kuma yana kiyaye shi da daidaito, har ma da launin fata, inganta ikon launi na launin, inganta ruwa na tsarin, inganta aikin sarrafawa, kuma a halin yanzu, yana iya rage yawan gogayya ta saman ta hanyar amfani da halayen ƙarancin kuzarin juyawa na sarkar silicon, don haka zai iya inganta santsi na saman samfuran. Kuma yana iya tabbatar da samar da santsi na juyawar extrusion.

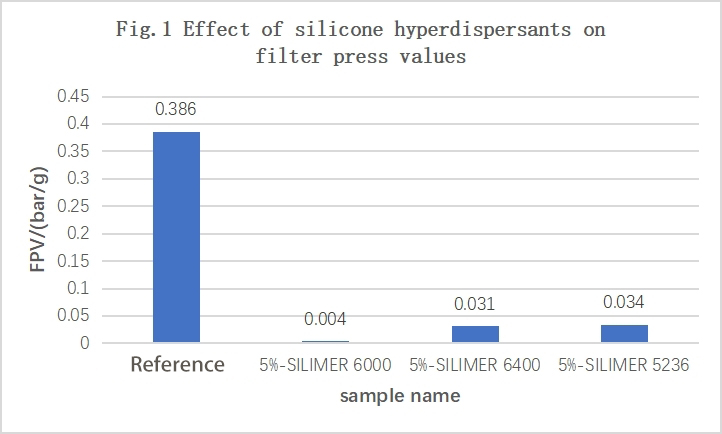

Kamar yadda aka nuna a Hoto na 1, a ƙarƙashin zafin gwaji: 235℃; jimlar samfurin: 1000g; nauyin launi: 80g; ƙarin masterbatch: 20%; substrate PP: 80%; ƙayyadaddun matattara: yanayin gwajin raga 1000, za a iya ganin cewa bayan ƙara SILIKE silicone hyperdispersantSILIMER6000, SILIMER6400, SILIMER5236zuwa ga masterbatch, ƙimar tace matsin lamba ta ragu sosai, wanda ke nuna cewaMaganin rage yawan sinadarin silicone na SILIKEyadda ya kamata a inganta yanayin tattara foda, sannan a ƙara inganta wargajewar foda. Ana iya amfani da mai wargajewa don inganta wargajewar foda.

Taimakon Tsarin Polymer na PPA kyauta na SILIKE PFAS, Cire karyewar narkewa & Faɗaɗa Tsarin Tsaftace Kayan Aiki

Matsala ta 3: Tsarin fitar da kayan aiki na musamman yana tara kayan aiki, kuma tsarin tsaftace kayan aiki yana da ɗan gajeren lokaci.

Binciken Dalilai: Saboda rashin daidaiton foda mai launi da kayan tushe, wani ɓangare na foda mai launi yana da sauƙin haɗuwa bayan haɗawa, akwai bambanci tsakanin ruwan foda mai launi da resin kuma ɗanɗanon narkewar yana da girma a cikin aikin fitarwa, a lokaci guda, akwai tasirin ƙazanta tsakanin kayan aikin fitar da ƙarfe da tsarin resin, wanda ke haifar da matattun kayan a cikin jikin ɗakin da fitar da bakin mutu, ana cire foda mai launi da resin thermoplastic yayin aiwatar da fitarwa wanda ke haifar da tarin abu a baki da mutu, kuma ana buƙatar rage rawar da ke tsakanin narkewar resin da kayan aikin ƙarfe don guje wa irin wannan yanayi. Ya zama dole a raunana hulɗar da ke tsakanin narkewar resin da kayan aikin ƙarfe don guje wa wannan yanayin.

Matsala ta 4: Karyewar narkewa yayin fitar da foda mai sauri, rabuwa da foda mai launi da kuma ruwan sama.

Binciken Dalilai: Ganin cewa mahimmin matakin yanke kayan da kansa yana da ƙanƙanta lokacin da aka fitar da tsarin foda mai launi a babban gudu, za a sami matsaloli masu tsanani na narkewar narkewa da taruwar mutu lokacin da aka fitar da shi a babban gudu, wanda zai haifar da rabuwa da hazo na foda mai launi. Fluoropolymer polymer ne mai yawan danko a cikin tsarin foda mai launi yayin da ake aiwatar da ƙaura ta waje ba shi da kyau, tasirin ingantawa gabaɗaya ne.

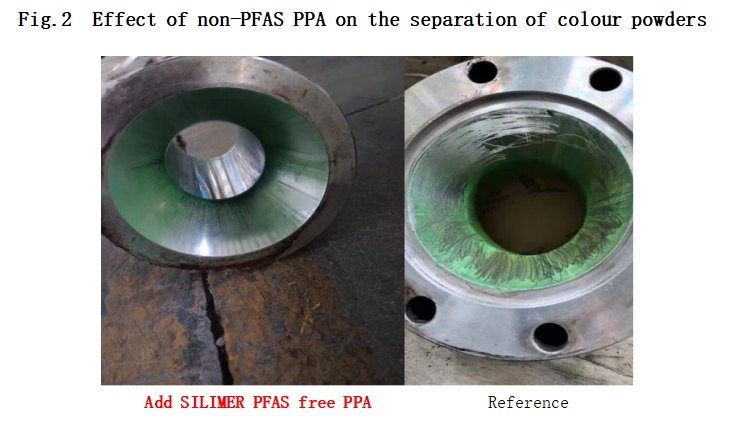

Mafita: Kayan aikin sarrafa PPA mara SILIKE PFASwani samfurin polysiloxane na musamman wanda aka gyara ta hanyar amfani da sinadarai wanda ya haɗu da sassan sarkar polysiloxane tare da ƙungiyoyin polar, yana haɗa kyakkyawan aikin duka biyun, da kuma haɓaka tsarin a lokaci guda. PPA mara fluorine yana ɗaukar ƙungiyoyin da aka gyara waɗanda za su iya haɗuwa da ƙarfi da sukurori na ƙarfe don maye gurbin rawar fluorine a cikin PPA mai ɗauke da fluorine, sannan yana amfani da halayen ƙarancin kuzari na silicone don ƙirƙirar fim ɗin silicone a saman kayan aikin ƙarfe don cimma tasirin keɓewa, wanda ke faɗaɗa zagayowar tsaftacewa na kayan aiki yadda ya kamata don rage lokacin aiki, kawar da karyewar narkewa, rage tarin mutu, da kuma inganta rawar ingancin saman. Bugu da ƙari, yana kuma da halaye na kariyar muhalli mara PFAS, rage ƙarfin fitarwa, inganta ruwa mai sarrafawa da sauransu.

Kamar yadda aka nuna a Hoto na 2, bayan abokin ciniki ya yi amfani da shiKayan Aikin Sarrafa Polymer mara SILIKE PFAS, daidai lokacin sarrafawa, foda mai launi da ke manne a bangon ciki na injin ya inganta sosai.

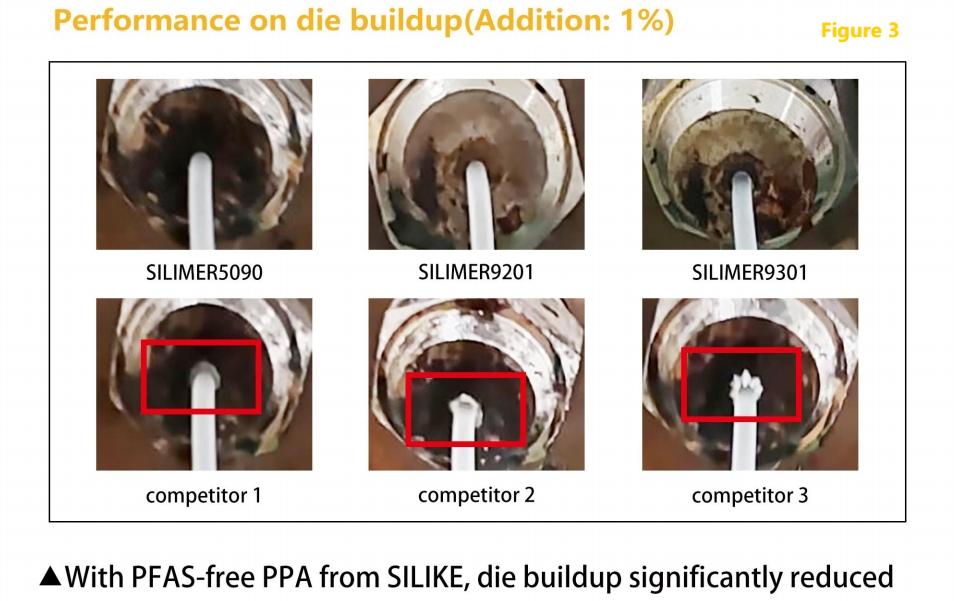

Kamar yadda aka nuna a Hoto na 3, ƙasa da yanayin fitar da ruwa na mintuna 30 da kuma adadin ƙari iri ɗaya, inganta SILIKE ba PFAS PPA akan tarin ruwa ya fi kyau fiye da na PPA mai fluorinated.

Masu kera kayan kwalliya na Masterbatch, idan kun fuskanci wata matsala ko matsala yayin sarrafa masterbatch, da fatan za a tuntuɓe mu, SILIKE na iya samar muku da mafita na musamman na sarrafa ma'auni.

Chengdu SILIKE Technology Co., Ltd, babban birnin kasar SinƘarin SiliconeMai samar da robobi da aka gyara, yana ba da mafita masu inganci don haɓaka aiki da aikin kayan filastik. Barka da zuwa tuntuɓar mu, SILIKE zai samar muku da ingantattun hanyoyin sarrafa robobi.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

gidan yanar gizo:www.siliketech.comdon ƙarin koyo.

Lokacin Saƙo: Oktoba-16-2024