Fahimtar Masana'antu kan Inganta Aikin Nailan a Aikace-aikacen da Aka Yi Amfani da Su sosai

A cikin yanayin da ake ci gaba da samun ci gaba a fannin robobi na injiniya, kayan nailan masu jure lalacewa suna ci gaba da taka muhimmiyar rawa a fannoni daban-daban na masana'antu. Daga kayan aikin mota zuwa injunan masana'antu, buƙatar mafita na nailan mai ɗorewa, mai ƙarancin gogayya ya haifar da babban ƙirƙira a fannin kimiyyar kayan aiki.

Na GargajiyaMafitazuwa juriya ga Nailan Wear

Al'ummar injiniyanci sun ƙirƙiro hanyoyi da dama da aka tabbatar da inganci don haɓaka juriyar lalacewa na PA6 da PA66, nau'ikan nailan da aka fi amfani da su a aikace-aikacen masana'antu.

1. Ƙarfafa Fiber na Gilashi:Ana samar da nailan mai ƙarfafa zare a gilashi (GF/PA6, GF/PA66) ta hanyar haɗa zare a gilashi cikin matrix na nailan, yana ƙirƙirar haɗakar aiki mai ƙarfi wanda ke inganta halayen injiniya sosai. Zare a cikin fiber suna samar da hanyar sadarwa ta 3D mai ƙarfafawa, suna haɓaka ƙarfin tauri (har zuwa 4×), tauri (ƙarfin lanƙwasa mai girma 3-5×), da juriyar zafi (ƙarfin HDT mai girma 50-100°C) ta hanyar canja wurin kaya mai inganci. Dangane da abubuwan da ke cikin fiber, waɗannan haɗakar sun kama daga ƙananan zare (10%-20%), matsakaicin zare (25%-35%), babban zare (40%-50%), da kuma babban zare (>50%). Yawan zare a cikin fiber da ya wuce 30% yana inganta juriyar sawa. Wannan haɗin ya sa ya zama babban zaɓi don aikace-aikacen masana'antu masu wahala.

2. Ƙarfafa Fiber na Carbon:Ƙara zare na carbon a cikin PA6/PA66 yana inganta ƙarfin injina da juriyar lalacewa sosai. Ba kamar sauran kayan ƙarfafawa ba, zare na carbon yana da laushi sosai tare da ƙarancin gogewa, yana hana lalacewar ƙarfe yayin gogayya. Matsakaicin ƙimar ƙarawa yana tsakanin 5% zuwa 20%, tare da aikace-aikacen da ke da inganci har zuwa 30%.

3. PTFE/PA6 gami:Tare da ƙarancin ma'aunin gogayya, PTFE yana samar da fina-finan mai mai a lokacin gogayya, wanda hakan ya sa ya dace musamman don aikace-aikacen da ke ɗauke da kaya mai yawa. Matsakaicin ƙimar ƙarawa a cikin PA6 yana tsakanin 15% zuwa 20%.

4. Molybdenum Disulfide (MoS2)/PA66 Alloys: A matsayin mai haɓaka lu'ulu'u, molybdenum disulfide yana ƙara lu'ulu'u na nailan, yana ƙirƙirar saman da ke da ƙarfi da juriya ga lalacewa. Babban kusancinsa ga karafa yana ba shi damar cike ƙananan ramuka a saman ƙarfe, yana ƙirƙirar hanyoyin haɗin gwiwa masu santsi. Wannan ya sa ya dace da aikace-aikacen gogayya tsakanin ƙarfe da nailan, tare da yawan ƙari na yau da kullun na 3% zuwa 15%.

5. PA66 da aka Gyara a Graphite:Ƙarin graphite yana rage yawan gogayya yadda ya kamata yayin da yake inganta halayen man shafawa kai tsaye. Tsarin graphite mai layi yana ba da damar zamewa cikin sauƙi yayin gogayya, yana rage lalacewa. Wannan gyare-gyaren yana da tasiri musamman a yanayin ruwa, tare da yawan ƙarawa tsakanin 3% da 15%.

Kalubalen da ke Faruwa a Juriyar Sakar Nailan: Daidaita Aiki, Farashi, da Dorewa

Duk da waɗannan hanyoyin magance matsalolin da aka kafa, masana'antun sun daɗe suna fama da daidaita buƙatun aiki da la'akari da farashi da kuma buƙatun dorewa. Ƙarin kayan abinci na gargajiya galibi suna buƙatar matakan lodi mai yawa, wanda zai iya shafar halayen sarrafawa da kuma ƙara farashin kayan aiki.

"Masana'antar tana neman mafita waɗanda za su iya samar da juriya ga lalacewa ba tare da wata matsala da ke tattare da ƙarin abubuwa na gargajiya ba," in ji wasu ƙwararrun injiniyan polymer. "Mafita mafi kyau zai buƙaci ƙarancin ƙarin kuɗi yayin da ake kiyaye ko ma inganta halayen injinan kayan tushe."

ƘirƙiraMagani don robobi na injiniyan nailan masu jure lalacewa

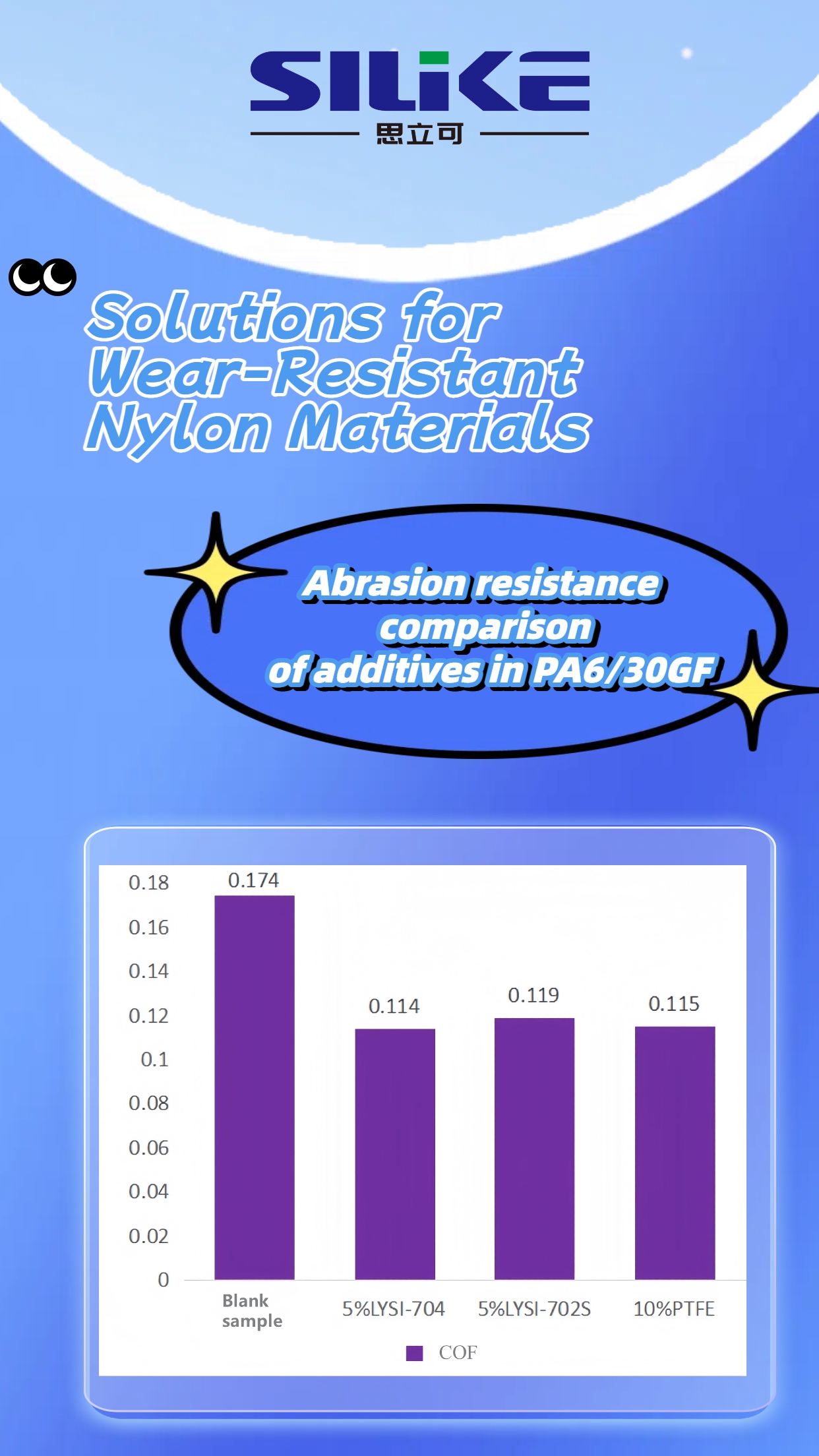

Kamfanin Chengdu Silike Technology Co., Ltd. ya kasance babban mai ƙirƙira kuma mai ƙera ƙarin sinadarai na silicone polymer masu inganci tun daga shekarar 2004. Muna da ƙwarewa a fannin fasahar silicone don masana'antar roba da robobi, muna ba da kayan aikin sarrafawa na zamani waɗanda ke magance ƙalubalen masana'antu masu sarkakiya da kuma haɓaka kaddarorin kayan aiki don aikace-aikacen masana'antu na duniya. Don mayar da martani ga waɗannan ƙalubalen, mun ƙirƙiri waniƙarin kayan maye mai jure lalacewa mai inganci wanda aka yi da silicone LYSI-704,an tsara shi don inganta gyaran nailan yayin da ake tallafawa samar da kayayyaki mai ɗorewa.

Me Yasa SILIKE Agent Mai Juriya Da Sakawa LYSI-704 Ya Canza Aikin Nailan? Me Ya Sa LYSI-704 Ya Bambanta?

Sabuwar ƙari mai hana lalacewa ta LYSI-704, wanda aka gina shi da tsarin polysiloxane na musamman, ba kamar ƙari na gargajiya da ke jure lalacewa ba, LYSI-704 yana samun yaɗuwa iri ɗaya a cikin matrices na nailan a ƙarancin ƙimar ƙari. Wannan yana ƙirƙirar layin shafawa mai ɗorewa wanda ke rage yawan gogayya yayin da yake kiyaye ingancin injina na kayan tushe.

"Abin da ya sa wannan fasaha ta zama abin birgewa musamman shine yanayinta mai aiki da yawa," in ji wani ƙwararre a fannin bincike da haɓaka fasaha daga SILIKE wanda ya mai da hankali kan amfani da silicone a cikin injiniyan robobi. "Lokacin da aka haɗa shi cikin tsarin fiber na gilashi na PA6+ ta hanyar haɗakar narkewa, LYSI-704 ba wai kawai yana ba da juriya ta musamman ga lalacewa kamar mafita na tushen PTFE ba, har ma yana inganta ƙarfin tasiri - haɗin da a da ake tunanin ba zai yiwu ba.

Wataƙila mafi mahimmanci ga masana'antun da ke da alaƙa da kayan kwalliya, ƙarin robobi / Mai Gyara LYSI-704 shi ma yana magance matsalar da ke ci gaba da yawo a kan zare wanda ya haifar da nailan da aka ƙarfafa da gilashi, yana buɗe sabbin damammaki don amfani inda ingancin saman yake da mahimmanci.

Bugu da ƙari, yayin da damuwar dorewa ke ci gaba da tsara shawarwarin zaɓin kayan aiki, sinadarai na LYSI-704 da ke amfani da silicone suna ba da madadin da ba shi da fluorine ga ƙarin PTFE na gargajiya, wanda ya dace da shirye-shiryen duniya don rage amfani da mahaɗan da aka yi da fluorine. Ikon fasahar na samar da ingantaccen aiki a ƙarancin ƙimar ƙari kuma yana fassara zuwa rage yawan amfani da albarkatu da yuwuwar rage sawun carbon a duk faɗin tsarin masana'antu.

Ga masana'antun filastik na injiniya waɗanda ke neman fa'idodi masu gasa ta hanyar ƙirƙirar kayan aiki, wannan fasahar ci gaba ta amfani da silicone tana ba da damammaki masu ban sha'awa a cikin kasuwa mai matuƙar wahala, yayin da take buɗe sabbin damammaki don haɓaka aikace-aikace.

Shin kuna shirye don haɓaka kayan aikin nailan ɗinku tare da sabuwar fasahar da ba ta jure lalacewa ba?

Idan kana nemaningantattun hanyoyin magance matsalar nailan don inganta juriyar lalacewasabbin abubuwa, kamar ƙarin kayan hana lalacewa na SILIKE LYSI-704 yana nuna sabuwar hanya ta kayan da aka ƙera, kuma shine ci gaban da kuke jira. Yana bayar da ingantaccen aiki mai ɗorewa.madadin ƙarin PTFE na gargajiyaTuntuɓe mu a yau don gano yadda wannan ƙarin kayan aiki da gyare-gyaren kirkire-kirkire zai iya canza robobi na injiniyanku yayin da yake daidaita manufofin dorewarku.

Tel: +86-28-83625089 or via Email: amy.wang@silike.cn. Website:www.siliketech.com

Lokacin Saƙo: Mayu-22-2025