A fannin robobi da rufi,cimma daidaiton yaɗuwar abubuwan cikawa, launuka, da abubuwan hana harshen wutaaiki ne mai matuƙar wahala amma mai wahala. Rashin kyawun watsawa na iya haifar da rashin daidaiton ingancin samfura, rashin ingantaccen aiki, rashin inganci, da kuma matsalolin muhalli. Ko kuna ƙera mahaɗan polymer, manyan batches, ko kuna magance zare-zare a cikin fenti ko shafi, ko rashin daidaiton juriyar wuta a cikin robobi, matsalolin watsawa na iya yin tasiri sosai ga aikin samfurin ku da gamsuwar abokin ciniki.

Me Yasa Watsawa Take Da Muhimmanci? Matsalar: Kalubalen Watsawa a Roba da Rufi

1. Ingancin Samfuri mara daidaituwa

Rashin kyawun watsawar abubuwan cikawa da launuka na iya haifar da rashin daidaiton launi, rashin kyawun kammala saman, da kuma rashin daidaiton halayen injiniya. Misali, watsawar launuka marasa daidaito a cikin fenti na iya haifar da zare ko tabo, yayin da rarrabawar abubuwa marasa daidaito a cikin robobi na iya haifar da rashin daidaiton juriyar wuta.

2. Rashin Ingantaccen Aiki

Rashin isasshen yaɗuwa sau da yawa yana buƙatar ƙarin lokacin sarrafawa, ƙaruwar amfani da makamashi, da ƙarin abubuwa masu yawa, wanda ke haifar da hauhawar farashi, jinkirin samarwa, da ƙaruwar yawan sharar gida.

3. Rashin Aiki Mai Kyau

Daga ƙarfin juriya zuwa juriyar zafi, watsawar abubuwan cikawa ko abubuwan hana harshen wuta mara daidaito na iya yin mummunan tasiri ga halayen injiniya da aikin samfurin ƙarshe.

4. Damuwar Muhalli

Yawan amfani da makamashi da kuma amfani da ƙarin abubuwa masu yawa suna taimakawa wajen haifar da sharar muhalli, wanda hakan ke ƙara yawan tasirin carbon a fannin samarwa.

Maganganu Masu Inganci: Magance Kalubalen Yaɗuwa

1. Inganta Zaɓin Launi: Zaɓi launuka masu girman barbashi da nau'in da ya dace don amfani.

2. Yi amfani da shiMasu Rarraba Inganci: Yi amfani da hyperdispersants don haɓaka watsawar launuka.

3. Daidaita Yawan: Tabbatar da yawan launuka da resins masu ɗaukar kaya sun daidaita don hana lalatawa.

Akwai wata mafita da za ta iya magance waɗannan matsalolin kai tsaye?Ana samun sabbin abubuwa don inganta watsawar launuka a cikin mahaɗan polymer?

Wadanne sinadarai ne suka fi tasiri wajen wargazawa ga sinadaran filastik, ko kuma nau'ikan launuka, ko kuma Coatings?

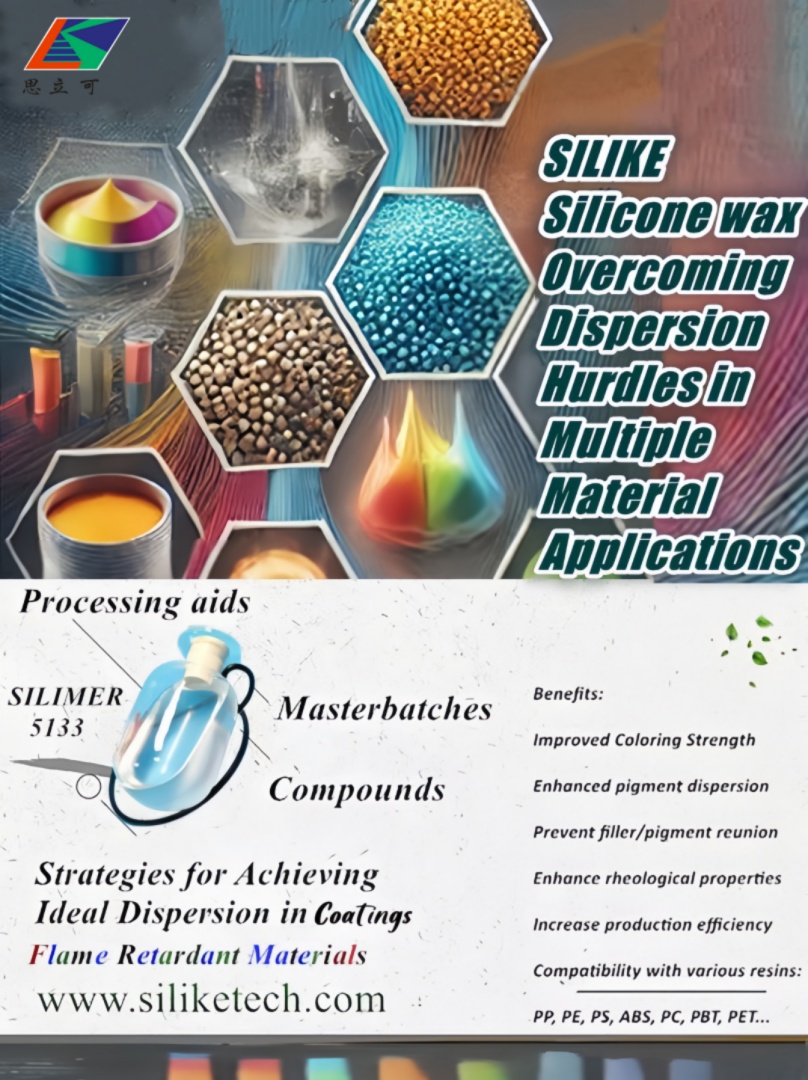

Gabatar da Sabbin Dabaru:kakin silicone SILIMER 5133as Ƙarin Copolysiloxane da Masu Gyara, daMafi Ingancin Watsawa ga Magungunan Roba, Manyan kwafi, da kuma Rufi

SILIMER 5133, wani siloxane mai sauƙin gyarawa na ruwa (silicon kakin zuma) daga SILIKE, shine siloxane na ruwa mai sauƙin gyarawa.sabuwar mafita da aka tabbatarga ƙalubalen warwatsewa a cikin mahaɗan filastik, manyan batches, da shafi. Haka kuma ana amfani da shi don magance saman abubuwan cikawa marasa tsari, launuka, da abubuwan hana harshen wuta, wanda ke inganta halayen warwatsewarsu sosai. Ga yadda zai iya inganta tsarin samar da ku:

Muhimman Fa'idodi Mai Rarraba Hyperdispersant SILIMER 5133 don Haɗin Roba, Batutuwa na Musamman & Rufi:

1. Babban Abun Ciki, Ingantaccen Watsawa: Hyperdispersant SILIMER 5133 yana samun rarrabawa iri ɗaya koda a lokacin da aka ƙara yawan cikawa.

2. Ingantaccen sheƙi da santsi a saman: SILIMER 5133 yana rage yawan gogayya (COF) don samun kyakkyawan gamawa.

3. Ingantaccen Yawan Narkewa: SILIMER 5133 yana inganta watsawar abubuwan cikawa da kuma ingancin sarrafawa.

4. Kyakkyawan Sakin Mold da Man Shafawa: SILIMER 5133 yana rage mannewa kuma yana inganta saurin samarwa.

5. Inganta Ƙarfin Launi: SILIMER 5133 yana ƙara wa launi ƙarfi ba tare da lalata halayen injiniya ba.

Me yasa za a zabi SILIMER 5133?

1. Amintaccen Masana'antu: Chengdu SILIKE Technology Co., Ltd. (wanda aka takaita a matsayin SILIKE) ya ƙware wajen haɓakawa da amfani da ƙarin abubuwa da aka yi da silicone don robobi da aka gyara, manyan batches, da mahaɗan roba. Muna amfani da shekaru da yawa na gogewa a fannin sinadarai na silicone da kimiyyar kayan aiki, muna ba da nau'ikan ƙarin abubuwa masu inganci don haɓaka sarrafawa da fasahar kula da yanayin zafi, haɓaka aiki, aiki, da dorewa.

2. Mai iya aiki iri-iri: Ya dace da nau'ikan sinadarai daban-daban na filastik, masters, da kuma rufin da aka yi amfani da su.

3. Dorewa: Yana rage tasirin muhalli ta hanyar rage sharar gida da amfani da makamashi.

Shin kuna shirye don magance tsarin samar da polymer ɗinku da kuma shawo kan ƙalubalen watsawa?

Tuntuɓi SILIKE don ƙarin koyo game da ƙarin kayan gyaran copolysiloxane SILIMER 5133 ko neman samfurin mumasu watsa kakin silicone,gami da mafita don watsawar launin fata,na'urar watsa launi ta musamman, na'urar watsawa ta filler,kayan watsawa ga masu hana harshen wuta, Mai watsawa ATH/MDH, mafita na watsawa don shafa, da kuma masu watsawa a cikin filastik. Bari kakin silicone ko silicone hyperdispersants na SILIKE su taimaka muku wajen samun daidaiton inganci, rage farashi, da kuma inganta inganci a cikin filastik ɗinku, manyan batches, da rufin ku. SILIKE ta himmatu wajen samar da ingantattun hanyoyin sarrafa filastik waɗanda aka tsara don takamaiman buƙatunku, haɓaka aiki mafi kyau da ƙima ga aikace-aikacenku.

Tel: +86-28-83625089 or via email: amy.wang@silike.cn, wshafin yanar gizo: www.siliketech.com

Lokacin Saƙo: Fabrairu-27-2025