Tsarin launi na musamman shine hanyar da aka fi amfani da ita wajen yin fenti ga robobi, wanda ake amfani da shi sosai a masana'antar sarrafa robobi. Ɗaya daga cikin mahimman alamomin aiki ga tsarin masterbatch shine yaɗuwar sa. Yaɗuwar yana nufin rarrabawar mai launi iri ɗaya a cikin kayan filastik. Ko a cikin tsarin allura, fitarwa, ko tsarin busawa, rashin kyawun yaɗuwa na iya haifar da rarraba launi mara daidaito, rabe-raben da ba daidai ba, ko ɗigo a cikin samfurin ƙarshe. Wannan batu babban abin damuwa ne ga masana'antun, kuma fahimtar dalilai da mafita yana da mahimmanci don kiyaye ingancin samfurin.

Dalilan Rashin Yaɗuwa a Tsarin Launi

Tarin Alamu

Masterbatch cakuda ne mai yawan gaske na launuka, kuma manyan tarin waɗannan launuka na iya yin tasiri sosai ga watsawa. Da yawa daga cikin launuka, kamar titanium dioxide da carbon black, suna taruwa tare. Zaɓar nau'in da ya dace da girman barbashi na launuka bisa ga samfurin ƙarshe da hanyar sarrafawa yana da mahimmanci don cimma kyakkyawan watsawa.

Tasirin Electrostatic

Yawancin na'urorin gwaji ba sa haɗa da sinadaran hana kumburi. Idan aka haɗa na'urorin gwaji da kayan aiki, ana iya samar da wutar lantarki mai tsauri, wanda ke haifar da haɗuwa mara daidaito da kuma rarraba launuka marasa daidaito a samfurin ƙarshe.

Ma'aunin Narkewa mara Dace

Masu samar da kayayyaki galibi suna zaɓar resins masu babban ma'aunin narkewa a matsayin mai ɗaukar nauyin masterbatch. Duk da haka, babban ma'aunin narkewa ba koyaushe yake mafi kyau ba. Ya kamata a zaɓi ma'aunin narkewa a hankali don dacewa da halayen zahiri da buƙatun saman samfurin ƙarshe, da kuma halayen sarrafawa na masterbatch. Ma'aunin narkewa wanda ya yi ƙasa sosai na iya haifar da ƙarancin wargajewa.

Rabon Ƙarawa Mai Ƙarawa

Wasu masu samar da kayayyaki suna tsara babban tsari tare da ƙarancin rabon ƙari don rage farashi, wanda zai iya haifar da rashin isasshen yaɗuwa a cikin samfurin.

Rashin Ingantaccen Tsarin Watsawa

Ana ƙara sinadaran warwatsewa da man shafawa a lokacin samar da masterbatch don taimakawa wajen wargaza tarin launuka. Idan aka yi amfani da magungunan warwatsewa ba daidai ba, hakan na iya haifar da rashin kyawun warwatsewa.

Rashin Daidaito Tsakanin Yawan Kauri

Manyan kwalaye galibi suna ɗauke da launuka masu yawan yawa, kamar titanium dioxide, wanda ke da yawan kusan 4.0g/cm³. Wannan ya fi yawa fiye da yawan kwalaye da yawa, wanda ke haifar da lalata babban kwalaye yayin haɗawa, wanda ke haifar da rarraba launuka marasa daidaito.

Zaɓin Mai Jigilar Kaya mara Kyau

Zaɓin resin mai ɗaukar kaya, wanda ke ɗauke da launuka da ƙari, yana da matuƙar muhimmanci. Abubuwa kamar nau'in, adadi, matsayi, da kuma ma'aunin narkewar mai ɗaukar kaya, da kuma ko yana cikin foda ko pellet, duk suna iya yin tasiri ga ingancin watsawa na ƙarshe.

Yanayin Sarrafawa

Yanayin sarrafa na'urar, gami da nau'in kayan aiki, hanyoyin haɗawa, da dabarun yin pelleting, suna taka muhimmiyar rawa a cikin watsawa. Zaɓuɓɓuka kamar ƙirar kayan haɗawa, tsarin sukurori, da hanyoyin sanyaya duk suna shafar aikin na'urar ...

Tasirin Tsarin Gyaran Mota

Tsarin gyaran musamman, kamar allurar ƙera, na iya shafar watsawa. Abubuwa kamar zafin jiki, matsin lamba, da lokacin riƙewa na iya shafar daidaiton rarraba launuka.

Kayan aiki Tufafi

Kayan aiki da ake amfani da su wajen ƙera filastik, kamar sukurori da suka lalace, na iya rage ƙarfin yankewa, wanda hakan ke raunana yaɗuwar babban rukunin.

Tsarin Motsa Jiki

Don ƙera allura, matsayin ƙofar da sauran fasalulluka na ƙirar mold na iya shafar samuwar samfura da watsawa. A cikin fitarwa, abubuwa kamar ƙirar manne da saitunan zafin jiki suma na iya shafar ingancin watsawa.

Magani Don Inganta Yaɗuwa a Tsarin Batun Launi, tattara launuka da mahadi

Idan aka fuskanci matsalar da ba ta da kyau, yana da muhimmanci a magance matsalar ta hanyar da ta dace:

Yi Aiki Tare A Fannin Ilimi: Sau da yawa, matsalolin wargajewa ba wai kawai suna faruwa ne saboda abubuwan da suka shafi kayan aiki ko tsari ba. Haɗin gwiwa tsakanin dukkan ɓangarorin da abin ya shafa, gami da masu samar da kayayyaki, injiniyoyin sarrafawa, da masana'antun kayan aiki, shine mabuɗin gano da magance tushen abubuwan da ke haifar da hakan.

Inganta Zaɓin Launi:Zaɓi launuka masu girman barbashi da nau'in da ya dace don takamaiman aikace-aikacen.

Wutar Lantarki Mai Tsayi:A haɗa magungunan hana haɗuwa marasa daidaito idan ya cancanta.

Daidaita Ma'aunin Narkewa:Zaɓi masu ɗaukar kaya masu ma'aunin narkewa wanda ya dace da yanayin sarrafawa da buƙatun samfur.

Rabon Karin Bayani: Tabbatar cewa an ƙara babban rukunin a cikin isassun adadin don cimma yaduwar da ake so.

Yi Tsarin Watsawa:Yi amfani da magungunan warwatsewa da man shafawa masu kyau don haɓaka lalacewar agglomerates na launuka masu haske.

Daidaita Yawan Da Yawa:Yi la'akari da yawan launuka da resins masu ɗauke da sinadarai don guje wa lalacewa yayin sarrafawa.

Sigogi na Sarrafa Gyaran Gyara:Daidaita saitunan kayan aiki, kamar yanayin zafi da sukurori, don haɓaka watsawa.

Ƙirƙira-kirkireMagani Don Inganta Yaɗuwa a Tsarin Batun Launi

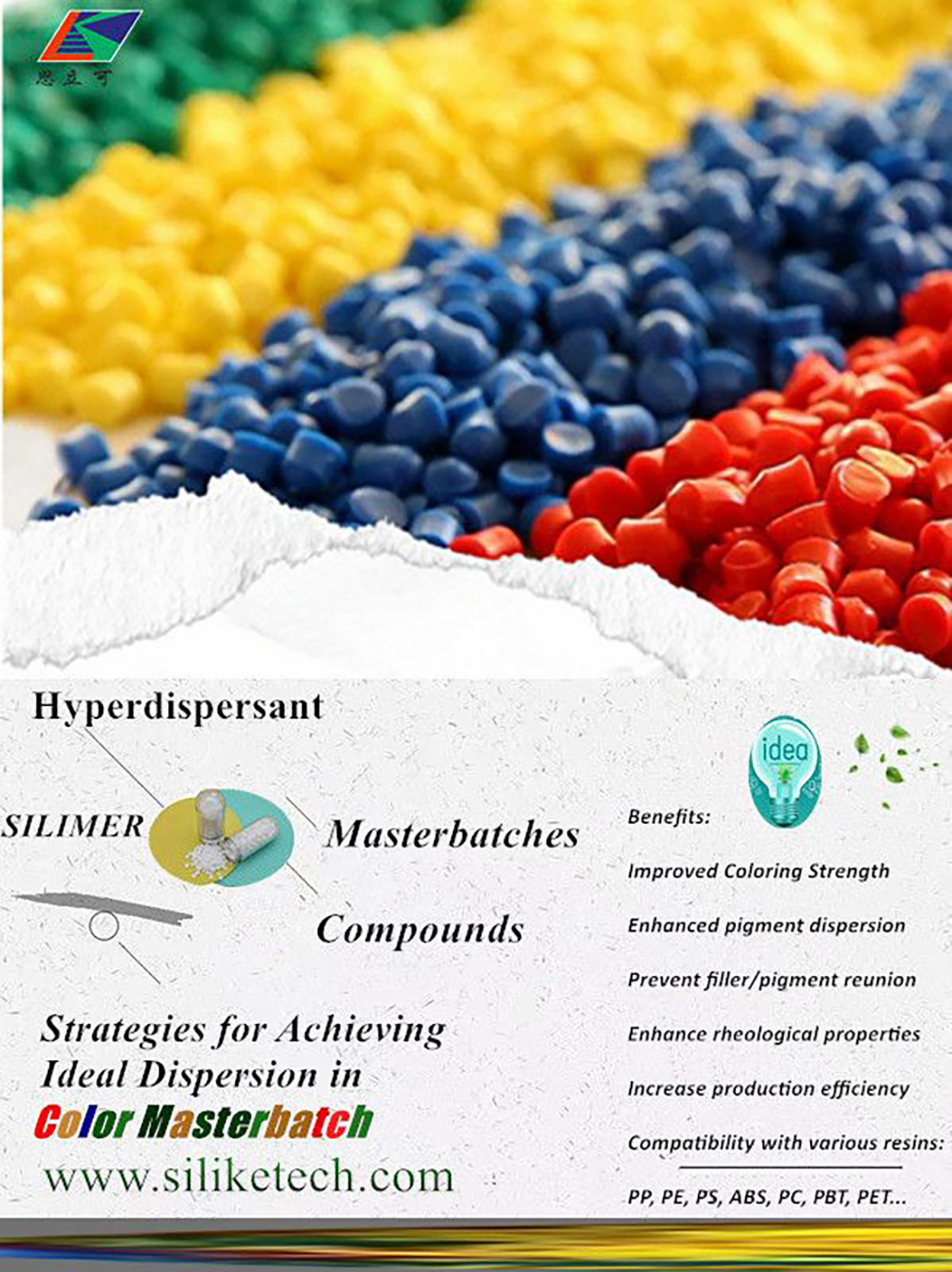

Sabuwar Silicone hyperdispersant, hanya mai inganci don magance Watsawa Mara Daidai a cikin Babban Batutuwan Launi tare daSILIKE SILIMER 6150.

SILIMER 6150wani kakin silicone ne da aka gyara wanda ke aiki a matsayin mai rage yawan ruwa, wanda aka tsara musamman don haɓaka ingancin tattarawar launuka, manyan batches, da mahadi. Ko dai watsawar launuka ne guda ɗaya ko tattarawar launuka da aka yi musamman, SILIMER 6150 ya yi fice wajen biyan buƙatun watsawa mafi wahala.

Afa'idodin SILIMER 6150don mafita na masterbatch masu launi:

Ingantaccen Watsawar Launi: SILIMER 6150yana tabbatar da rarraba launuka iri ɗaya a cikin matrix na filastik, yana kawar da ɗigon launuka ko ɗigon da kuma tabbatar da daidaiton launi a cikin kayan.

Inganta Ƙarfin Launi:Ta hanyar inganta watsawar launuka,SILIMER 6150yana ƙara ƙarfin launi gabaɗaya, yana bawa masana'antun damar cimma ƙarfin launi da ake so tare da ƙarancin launin launi, wanda ke haifar da samarwa mafi inganci da araha.

Rigakafin Haɗuwa da Mai Cika da Launi: SILIMER 6150yana hana launuka da abubuwan cikawa haɗuwa yadda ya kamata, yana tabbatar da cewa bazuwar ta kasance mai dorewa kuma mai dorewa a duk lokacin da ake sarrafa ta.

Ingancin Halayen Rheulic: SILIMER 6150Ba wai kawai yana inganta watsawa ba, har ma yana haɓaka halayen rheological na narkewar polymer. Wannan yana haifar da ingantaccen sarrafawa, rage ɗanko, da haɓaka halayen kwarara, waɗanda suke da mahimmanci don samar da filastik mai inganci.

IƘara Ingantaccen Samarwa da Rage FarashiTare da ingantaccen watsawa da ingantaccen halayen rheological,SILIMER 6150yana ƙara ingancin samarwa, yana ba da damar saurin lokacin sarrafawa da rage sharar kayan aiki, wanda a ƙarshe ke rage farashin samarwa gaba ɗaya.

Dacewar Faɗi: SILIMER 6150Yana dacewa da nau'ikan resins iri-iri, gami da PP, PE, PS, ABS, PC, PET, da PBT, wanda hakan ya sa ya zama zaɓi mafi kyau ga aikace-aikace daban-daban a masana'antar filastik ta musamman da kuma masana'antar sinadarai masu haɗaka.

Inganta samar da launuka na musamman tare daSILIMER 6150don ingantaccen watsa launuka da ingantaccen aikin samfur. Kawar da alamun launi da kuma ƙara inganci. Kada ka rasa komai—inganta watsawa, rage farashi, da kuma ƙara ingancin babban rukunin ku.Siliki Mai Saduwa yau! Waya: +86-28-83625089, Imel:amy.wang@silike.cn,Ziyarciwww.siliketech.comdon ƙarin bayani.

Lokacin Saƙo: Agusta-15-2024