Babban rukunin siliconewani nau'in ƙari ne a masana'antar roba da filastik. Fasaha mai ci gaba a fannin ƙarin silicone ita ce amfani da polymer silicone mai nauyin ƙwayoyin halitta mai yawa (UHMW) (PDMS) a cikin resin thermoplastic daban-daban, kamar LDPE, EVA, TPEE, HDPE, ABS, PP, PA6, PET, TPU, HIPS, POM, LLDPE, PC, SAN, da sauransu. Kuma a matsayin ƙananan ƙwayoyi don ba da damar ƙarawa kai tsaye zuwa thermoplastic yayin sarrafawa. Haɗa ingantaccen sarrafawa tare da farashi mai araha. Babban ma'aunin silicone yana da sauƙin ciyarwa, ko haɗawa, cikin robobi yayin haɗawa, fitarwa, ko ƙera allura. Ya fi man kakin zuma na gargajiya da sauran ƙari don inganta zamewa yayin samarwa. Don haka, masu sarrafa filastik sun fi son amfani da su a cikin fitarwa.

MatsayinƘarin Silicone MasterbatchInganta Sarrafa Roba

Babban batirin silicone yana ɗaya daga cikin shahararrun zaɓuɓɓuka ga masu sarrafawa a fannin sarrafa filastik da inganta ingancin saman. A matsayin nau'in mai mai ƙarfi. Yana da manyan ayyuka masu zuwa idan aka yi amfani da shi a cikin resin thermoplastic:

A. Inganta kwararar resin da sarrafawa;

Ingantaccen cika mold da kuma sakin mold

Rage ƙarfin fitarwa da inganta ƙimar fitarwa;

B. Yana inganta halayen saman resin

Inganta saman filastik, santsi mai kyau, da rage yawan gogayya na fata, Inganta juriyar lalacewa da juriyar karce;

Kuma silicone masterbatch yana da kyakkyawan kwanciyar hankali na thermal (zafin jiki na bazuwar thermal yana da kusan 430 ℃ a cikin nitrogen) da kuma rashin ƙaura;

Kare muhalli;

Hulɗa da abinci cikin aminci.

Dole ne mu nuna cewa duk ayyukan silicone masterbatches mallakar A da B ne (maki biyu da muka lissafa a sama) amma ba maki biyu masu zaman kansu ba ne amma

suna ƙara wa junansu ƙarfi, kuma suna da alaƙa ta kut-da-kut.

Tasiri akan samfuran ƙarshe

Saboda halayen tsarin kwayoyin halitta na siloxane, yawan shan maganin yana da ƙanƙanta sosai don haka gaba ɗaya kusan babu wani tasiri ga kayan aikin injiniya na samfuran ƙarshe. Gabaɗaya magana, sai dai tsawaitawa da ƙarfin tasiri zai ƙaru kaɗan, ba tare da wani tasiri ga wasu kayan aikin injiniya ba. A babban allurai, yana da tasirin haɗin gwiwa tare da magungunan hana ƙonewa.

Saboda kyakkyawan aikin da yake yi akan juriya mai yawa da ƙarancin zafin jiki, ba zai yi wani illa ga juriya mai yawa da ƙarancin zafin jiki na samfuran ƙarshe ba. Yayin da kwararar resin, sarrafawa, da halayen saman za a inganta a bayyane kuma COF zai ragu.

Tsarin aiki

Batutuwan Silicone na musammanpolysiloxane ne mai nauyin kwayoyin halitta mai matuƙar girma wanda aka watsa a cikin resins daban-daban wanda shine nau'in aikin masterbatch. Lokacin da nauyin kwayoyin halitta mai matuƙar girma.manyan batches na siliconeAna ƙara su a cikin robobi don ba su da polar kuma tare da ƙarancin kuzarin saman, yana da yanayin ƙaura zuwa saman filastik yayin aikin narkewa; yayin da, tunda yana da babban nauyin kwayoyin halitta, ba zai iya motsawa gaba ɗaya ba. Don haka muna kiransa jituwa da haɗin kai tsakanin ƙaura da rashin ƙaura. Saboda wannan siffa, wani Layer mai aiki mai ƙarfi da aka samar tsakanin saman filastik da sukurori.

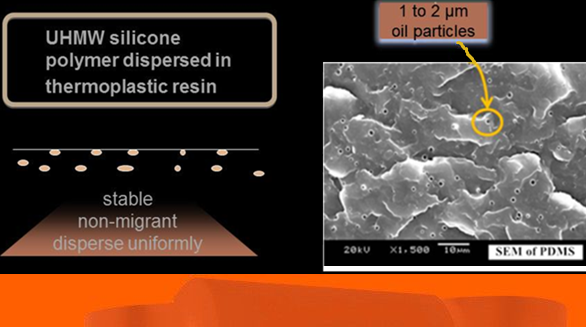

Tare da ci gaba da sarrafawa, ana ci gaba da cire wannan layin shafawa da samar da shi. Don haka kwararar resin da sarrafawa suna inganta akai-akai kuma suna rage wutar lantarki, ƙarfin kayan aiki da inganta fitarwa. Bayan sarrafa sukurori biyu, za a rarraba ma'aunin silicone daidai gwargwado a cikin robobi kuma su samar da barbashi mai 1 zuwa 2-micron a ƙarƙashin na'urar hangen nesa, waɗannan barbashin mai za su ba samfuran kyakkyawan kamanni, jin daɗi a hannu, ƙarancin COF, da kuma juriya ga gogewa da karce.

Daga hoton za mu iya ganin cewa silicone zai zama ƙananan ƙwayoyin cuta bayan an warwatse su a cikin robobi, abu ɗaya da muke buƙatar nuna shi ne cewa watsewa shine babban ma'aunin ma'aunin silicone, ƙaramin ƙwayoyin, idan aka rarraba su daidai, za mu sami sakamako mafi kyau.

Lokacin Saƙo: Mayu-26-2023