Zamewar SILIMER jerin ba tare da ruwa ba da kuma babban tsari na hana toshewa don fim ɗin marufi na abinci

Farin foda da ke kwarara a cikin jakar marufi na abinci ya faru ne saboda sinadarin zamiya (oleic acid amide, erucic acid amide) da masana'antar fim ɗin ke amfani da shi yana zubewa, kuma hanyar da maganin zamiya na amide na gargajiya ke amfani da ita ita ce sinadarin da ke aiki yana ƙaura zuwa saman fim ɗin, yana samar da wani Layer na mai mai da ƙwayoyin halitta guda ɗaya kuma yana rage yawan gogayya na saman fim ɗin. Duk da haka, saboda ƙaramin nauyin ƙwayoyin halitta na maganin zamiya na amide, yana da sauƙin zubewa ko foda, don haka foda yana da sauƙin kasancewa a kan abin naɗin da aka haɗa yayin aikin haɗa fim ɗin, kuma foda da ke kan abin naɗin roba za a manne shi yayin sarrafa fim ɗin, wanda ke haifar da farin foda a bayyane akan samfurin ƙarshe.

Domin magance matsalar saurin saukar ruwan maganin amide na gargajiya, SILIKE ta ƙirƙiro wani samfurin co-polysiloxane da aka gyara wanda ya ƙunshi ƙungiyoyin aiki na halitta masu aiki -Zamewar fim ɗin Silimer ba tare da ruwan sama baKa'idar aiki ta wannan samfurin ita ce: Dogon sarkar carbon da resin sun dace don taka rawar da aka sanya a cikin bututun, kuma sarkar silicone tana ƙaura zuwa saman fim ɗin don taka rawar zamewa, don haka zai iya taka rawar zamewa ba tare da cikakken ruwan sama ba. An ba da shawarar maki:SILIMER5064, SILIMER5064MB1, SILIMER5064MB2, SILIMER5065HB...

•Fa'idodin da aka saba amfani da su na samfur

•Kyakkyawan juriya ga zafin jiki mai yawa

•Aiki mai santsi mai ɗorewa

•Lafiya kuma babu ƙamshi

•Ba ya shafar buga fim, haɗakarwa, bayyana gaskiya

•Ana amfani da shi sosai a cikin fina-finan BOPP/CPP/PE/PP.....

•Wasu bayanai masu dacewa game da gwajin aiki

Yadda ya kamata rage yawan gogayya, ba ya shafar matakin hazo da watsawa

Tsarin substrate da aka kwaikwayi: 70%LLDPE, 20%LDPE, 10% metallocene PE

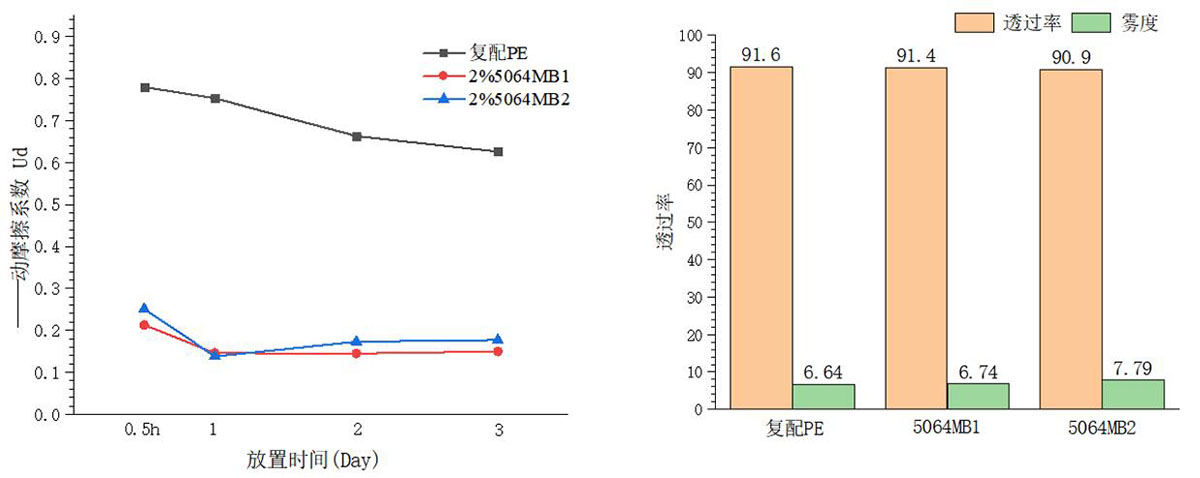

Kamar yadda aka nuna a Hoto na 1, an rage yawan gogayya na fim ɗin bayan an ƙara kashi 2% na SILIMER 5064MB1 da kashi 2% na SILIMER 5064MB2 idan aka kwatanta da PE mai haɗaka. Bugu da ƙari, kuma kamar yadda aka nuna a Hoto na 2, ƙarin SILIMER 5064MB1 da SILIMER 5064MB2 bai shafi matakin hazo da watsa fim ɗin ba.

•Ma'aunin gogayya yana da karko

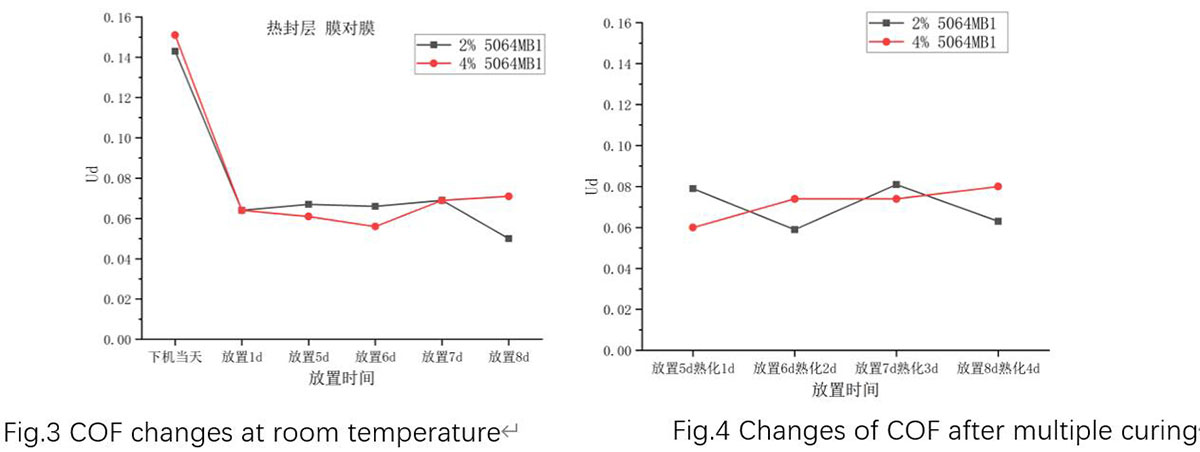

Yanayin warkewa: zafin jiki 45℃, zafi 85%, lokaci 12h, sau 4

Kamar yadda aka nuna a Hoto na 3 da Hoto na 4, za a iya ganin cewa ma'aunin gogayya na fim ɗin bayan ƙara 2% SILIMER 5064MB1 da 4% SILIMER 5064MB1 yana nan a ƙimar da ta dace bayan an gama shafawa da yawa.

• Faɗin fim ɗin ba ya zubewa kuma baya shafar ingancin kayan aiki da samfurin ƙarshe

Kamar yadda aka nuna a hoton da ke ƙasa, yi amfani da zane baƙi don goge saman fim ɗin da samfurin amide da SILIMER. Za a iya gani idan aka kwatanta da amfani da ƙarin amide,Jerin SILIMERbaya fashewa adn ba shi da wani foda mai saukowa.

•Warware matsalar farin foda a cikin abin naɗin haɗin gwiwa da jakar samfurin ƙarshe

Kamar yadda aka nuna a cikin hoton da ke ƙasa, bayan na'urar haɗakarwa ta wuce mita 6000 na fim ɗin tare da amide na erucic acid, akwai tarin farin foda a bayyane, kuma akwai farin foda a bayyane akan jakar samfurin ƙarshe; Duk da haka, ana amfani da shi tare daJerin SILIMERZa mu iya ganin lokacin da na'urar haɗakarwa ta wuce mita 21000, kuma jakar samfurin ƙarshe ta kasance mai tsabta da sabo.

Ƙara amide

Ƙara jerin Silimer

SILIMER ba tare da ruwan sama ba fim ɗin masterbatch, kiyaye ƙofar farko ta amincin abinci, tabbatar da tsaron nauyin marufin abinci! Idan kun cika wasu tambayoyi game da jakunkunan marufin abinci ko wasu fina-finai, da fatan za a tuntuɓe mu, za mu yi farin cikin tsara muku mafita!